Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Release time:

2025-06-28

Maximizing Performance with Japanese Standard Flanges in Your Pipeline Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flanges: The Basics 3. Benefits of Japanese Standard Flanges 4. Applications of Japanese Standard Flanges in Various Industries 5. Selecting the Right Japanese Standard Flanges for Your Pipeline 6. Installation Tips for Japa

Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Table of Contents

- 1. Introduction to Japanese Standard Flanges

- 2. Understanding Flanges: The Basics

- 3. Benefits of Japanese Standard Flanges

- 4. Applications of Japanese Standard Flanges in Various Industries

- 5. Selecting the Right Japanese Standard Flanges for Your Pipeline

- 6. Installation Tips for Japanese Standard Flanges

- 7. Maintenance Practices for Longevity

- 8. Common Issues and Solutions with Japanese Standard Flanges

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Japanese Standard Flanges

Japanese standard flanges are essential components in the world of piping systems. They serve as crucial connectors, allowing various piping elements to join seamlessly, thus ensuring the integrity and efficiency of fluid transport. Given Japan's rigorous engineering standards, flanges manufactured under these specifications are renowned for their precision, durability, and performance. In this article, we will explore how these flanges can maximize the performance of your pipeline systems, ultimately enhancing operational efficiency and safety.

2. Understanding Flanges: The Basics

Flanges are flat pieces of metal used to connect two piping sections, valves, pumps, or any other equipment within a piping system. They are typically made from materials such as steel, stainless steel, and plastic, depending on the application. Flanges enable easy assembly and disassembly of piping systems, making maintenance and repairs more convenient.

There are several types of flanges, including:

- **Weld Neck Flanges**: Ideal for high-pressure applications, offering a strong connection.

- **Slip-on Flanges**: Easy to install, they slide over the pipe and are welded in place.

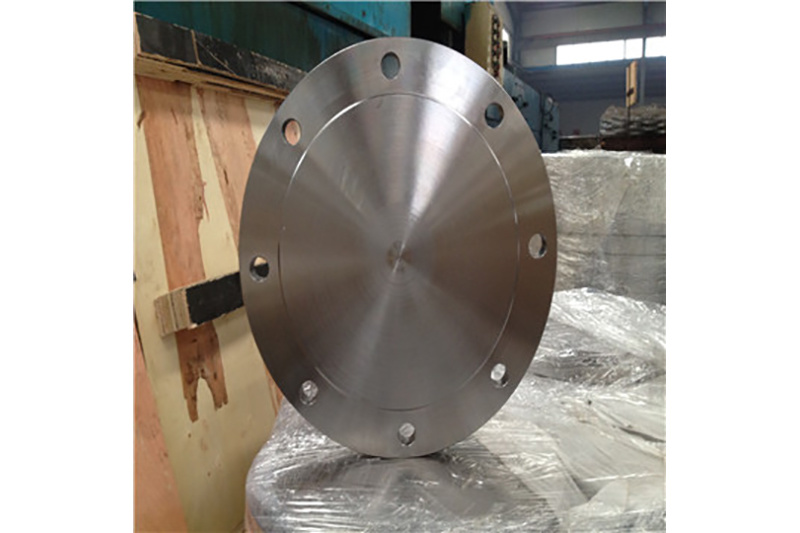

- **Blind Flanges**: Used to seal off a piping system, preventing fluid from passing through.

- **Socket Weld Flanges**: Suitable for small diameter pipes, they provide a strong connection by welding inside the flange.

Japanese standard flanges, specifically, adhere to the JIS (Japanese Industrial Standards) guidelines, ensuring precision and compatibility across various applications.

3. Benefits of Japanese Standard Flanges

Utilizing Japanese standard flanges in your pipeline system comes with a multitude of advantages:

3.1 Superior Quality and Reliability

Japanese manufacturers are known for their stringent quality control processes. Each flange produced meets the highest industry standards, ensuring reliability in demanding environments.

3.2 Enhanced Performance

With their precise dimensions and robust materials, Japanese standard flanges minimize leak potential and maintain pressure integrity, optimizing overall system performance.

3.3 Versatility

These flanges can be used in various industries, including oil and gas, chemical processing, and water supply, making them highly versatile.

3.4 Cost-Effectiveness

While the initial investment might be higher than other alternatives, the long-term savings on maintenance and repair often justify the cost. High-quality flanges reduce the need for frequent replacements and repairs.

3.5 Compliance with International Standards

Japanese standard flanges are designed to meet international specifications, making them suitable for projects worldwide without compatibility issues.

4. Applications of Japanese Standard Flanges in Various Industries

Japanese standard flanges find applications across a multitude of sectors:

4.1 Oil and Gas Industry

In this sector, flanges must withstand high pressures and corrosive environments. Japanese standard flanges provide the robustness and reliability needed for safe transport of crude oil and natural gas.

4.2 Chemical Processing

Chemical plants require flanges that can handle aggressive substances. The materials used in Japanese standard flanges offer excellent corrosion resistance, making them ideal for this application.

4.3 Water Treatment Facilities

Flanges in water treatment plants must ensure leak-proof connections. Japanese standard flanges help maintain water quality and system integrity by preventing leaks.

4.4 Food and Beverage Industry

In this sanitary-sensitive industry, flanges must meet strict hygiene standards. Japanese standard flanges are manufactured using materials that are easy to clean and maintain.

5. Selecting the Right Japanese Standard Flanges for Your Pipeline

Choosing the right flanges for your system is critical for optimal performance. Consider the following criteria during the selection process:

5.1 Material Compatibility

Ensure that the flange material is compatible with the fluid being transported. For corrosive liquids, stainless steel or specialized alloys are recommended.

5.2 Pressure Rating

Flanges come with various pressure ratings. It is essential to select a flange that can handle the maximum pressure in your system to prevent failure.

5.3 Size and Dimension

The size of the flange must match the pipe diameter. Accurate measurements are crucial to ensure proper fit and function.

5.4 Type of Flange

Based on your application, choose the appropriate type of flange—weld neck, slip-on, blind, or socket weld. Each type serves a specific purpose and offers unique benefits.

6. Installation Tips for Japanese Standard Flanges

Proper installation is vital for ensuring the longevity and efficiency of flanges in your pipeline system. Follow these guidelines:

6.1 Prepare the Surface

Ensure that the mating surfaces of the flanges are clean and free from dirt, debris, and corrosion. This step is essential for achieving a tight seal.

6.2 Use Gaskets Appropriately

Select gaskets that are compatible with the fluid and temperature conditions of your application. Proper gasket selection can prevent leaks and enhance performance.

6.3 Tightening Sequence

Follow a specific tightening sequence to distribute stress evenly across the flange. This practice helps prevent warping and ensures a secure connection.

6.4 Avoid Over-tightening

While it is important to secure flanges tightly, over-tightening can lead to flange deformation and potential failure. Always refer to manufacturer specifications for torque requirements.

7. Maintenance Practices for Longevity

To maximize the lifespan of your Japanese standard flanges, implement regular maintenance practices:

7.1 Regular Inspections

Conduct routine inspections to identify signs of wear, corrosion, or leakage. Early detection of issues can save on repair costs and prevent system failures.

7.2 Cleaning

Depending on the fluid transported, flanges may require periodic cleaning to remove any buildup. Ensure that cleaning methods do not damage the flange material.

7.3 Monitoring Operating Conditions

Keep an eye on operating pressures and temperatures, ensuring they remain within acceptable limits to avoid undue stress on the flanges.

8. Common Issues and Solutions with Japanese Standard Flanges

Even with high-quality Japanese standard flanges, issues can arise. Here are some common problems and their solutions:

8.1 Leakage

**Solution**: Check for proper installation, including the correct use of gaskets and tightening sequences. If leaks persist, inspect for damage to the flange or pipe.

8.2 Corrosion

**Solution**: Regularly inspect flanges for signs of corrosion. Consider applying protective coatings or switching to more corrosion-resistant materials.

8.3 Flange Warping

**Solution**: Ensure flanges are not over-tightened during installation. Regularly inspect for warping and replace damaged flanges promptly.

9. Conclusion

In conclusion, Japanese standard flanges are an integral part of ensuring optimal performance in pipeline systems. Their superior quality, reliability, and versatility make them a preferred choice across various industries. By understanding their benefits, applications, and maintenance practices, you can maximize your pipeline's efficiency and longevity. Investing in high-quality flanges and following proper installation and maintenance guidelines will lead to a more reliable and effective piping system.

10. Frequently Asked Questions

1. What are Japanese standard flanges?

Japanese standard flanges are piping components manufactured in accordance with Japanese Industrial Standards (JIS), ensuring high-quality materials and precise dimensions.

2. What industries use Japanese standard flanges?

These flanges are widely used in industries such as oil and gas, chemical processing, water treatment, and food and beverage.

3. How do I select the right flange for my application?

Consider factors such as material compatibility, pressure rating, size and dimension, and the type of flange needed for your specific application.

4. What are the common types of flanges?

Common flange types include weld neck, slip-on, blind, and socket weld flanges, each serving different purposes in a piping system.

5. How often should I inspect my flanges?

Regular inspections should be conducted at least twice a year or more frequently in critical applications to ensure optimal performance and early detection of potential issues.

Previous

Latest developments

Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Maximizing Performance with Japanese Standard Flanges in Your Pipeline Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flanges: The Basics 3. Benefits of Japanese Standard Flanges 4. Applications of Japanese Standard Flanges in Various Industries 5. Selecting the Right Japanese Standard Flanges for Your Pipeline 6. Installation Tips for Japa

Understanding American Standard Flanges: Key Insights for Construction and Decoration Materials

American standard flanges are critical components in piping systems, particularly in the construction and decoration materials sector. They serve as connections between two sections of pipe, allowing for the secure assembly and disassembly of piping systems without compromising the integrity of the overall structure. Understanding the key attributes of American standard flanges can significantly e

Maintaining Your Threaded Flanges: Expert Tips for Longevity in Construction and Decoration

Maintaining Your Threaded Flanges: Tips for Longevity Table of Contents Understanding Threaded Flanges The Importance of Maintenance for Threaded Flanges Common Issues with Threaded Flanges and Their Solutions Best Practices for Maintaining Threaded Flanges Protective Coatings and Treatments for Threaded Flanges How to Inspect Threaded Flanges Effectively When to Repla

Understanding Flanged Connections: Essential Insights for Building and Decorative Materials

Flanged connections are a pivotal aspect of piping systems, specifically designed to join two sections of pipe or a pipe to a valve or fitting. These connections utilize flanges—flat pieces of material with holes for bolts—that create a secure seal between components. A properly executed flanged connection ensures the integrity and efficiency of fluid transport systems, making it an essential topi

Top 5 Advantages of Incorporating Sliding Flanges in Your Designs

Top 5 Advantages of Incorporating Sliding Flanges in Your Designs Introduction to Sliding Flanges In the world of construction and design materials, sliding flanges stand out as a crucial component that facilitates a variety of applications. These unique connections allow for flexibility in piping systems, making them indispensable in many industrial and architectural projects. Understanding the

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, also known as long neck flanges, are specialized connectors used in piping systems. Unlike standard flanges, they feature an extended neck that provides additional height to the flange face. This design is particularly beneficial in applications requiring higher alignment precision and enhanced sealing capabilities. The extended neck allows for better support and alignment of th