Understanding High Neck Flanges: Essential Components in Construction and Decoration

Release time:

2025-06-23

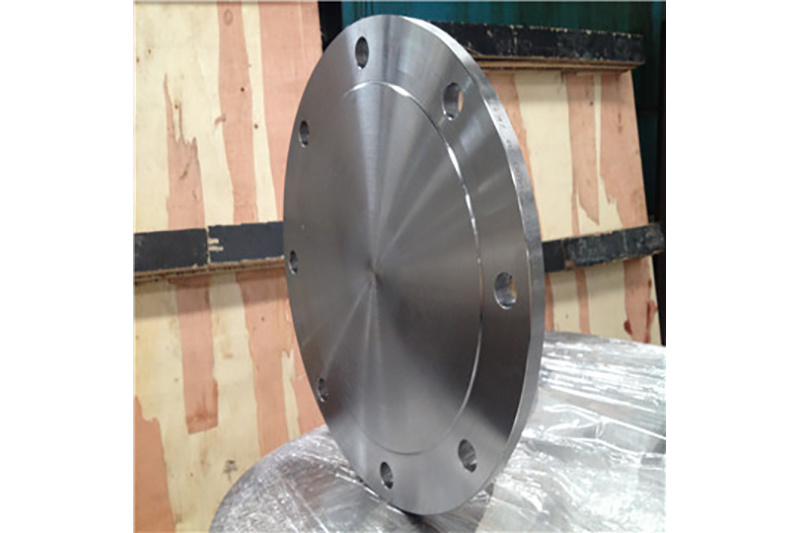

High neck flanges, also known as long neck flanges, are specialized connectors used in piping systems. Unlike standard flanges, they feature an extended neck that provides additional height to the flange face. This design is particularly beneficial in applications requiring higher alignment precision and enhanced sealing capabilities. The extended neck allows for better support and alignment of th

One of the primary advantages of high neck flanges is their ability to accommodate thermal expansion and contraction of the piping system. In projects where temperature fluctuations are anticipated, these flanges help maintain tight seals, preventing leaks and ensuring system integrity. The additional height also allows for easier installation of gaskets and sealing materials, further enhancing the reliability of the connection.

High neck flanges are widely used in various industries, including oil and gas, chemical processing, and water treatment. Their robust design makes them suitable for both industrial and commercial applications. When selecting high neck flanges for a project, it is crucial to consider factors such as material compatibility, pressure ratings, and the specific requirements of the piping system. Common materials for these flanges include carbon steel, stainless steel, and various alloys, each chosen based on the unique demands of the application.

Another important aspect of high neck flanges is their versatility. They can be manufactured in various sizes and configurations to meet the needs of different projects. Additionally, they can be designed to conform to various industry standards, ensuring compatibility with existing systems and components. This flexibility makes high neck flanges a preferred choice for engineers and contractors seeking reliable solutions in their piping projects.

Furthermore, the installation of high neck flanges requires adherence to industry best practices to maximize their effectiveness. Proper alignment, torque specifications, and the use of appropriate sealing materials are essential to achieve optimal performance. Professionals in the field are advised to be familiar with these practices to ensure the durability and functionality of the piping system.

In conclusion, high neck flanges are vital components in modern construction and decorative materials, offering enhanced sealing and support in piping systems. Their unique design and versatility make them suitable for a wide range of applications, and understanding their characteristics can significantly benefit professionals in the industry. By selecting the right high neck flanges and following best practices for installation, project stakeholders can ensure the longevity and efficiency of their piping systems.

Latest developments

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, also known as long neck flanges, are specialized connectors used in piping systems. Unlike standard flanges, they feature an extended neck that provides additional height to the flange face. This design is particularly beneficial in applications requiring higher alignment precision and enhanced sealing capabilities. The extended neck allows for better support and alignment of th

The Evolution of Flat Flanges in Building Materials: A Comprehensive Insight

The Evolution of Flat Flanges in Building Materials Introduction to Flat Flanges in the Construction Industry Flat flanges are critical components in various piping and construction applications, serving as flat surfaces for connecting pipes, valves, and other equipment. Their evolution reflects advancements in engineering, material science, and design, contributing to the efficiency and safety of

Understanding Steel Industries Forgings: Key Insights for Professionals

Steel industries forgings play a crucial role in the manufacturing of high-performance components that are integral to various sectors, particularly in construction and decorative materials. Forgings are produced by shaping metal through localized compressive forces, which can be applied through hammers or presses. This manufacturing process not only improves the mechanical properties of the steel

The Role of Forging in Enhancing Stainless Steel Properties: An In-Depth Exploration

The Role of Forging in Enhancing Stainless Steel Properties Table of Contents 1. Introduction to Stainless Steel and Forging 2. Overview of Forging Techniques 3. The Impact of Forging on Stainless Steel Properties 3.1 Enhancing Mechanical Strength 3.2 Improving Corrosion Resistance 3.3 Increasing Ductility and Toughness 4. Types of Forged Stainless Steel 5. Applications of Forged

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various