The Evolution of Flat Flanges in Building Materials: A Comprehensive Insight

Release time:

2025-06-22

The Evolution of Flat Flanges in Building Materials Introduction to Flat Flanges in the Construction Industry Flat flanges are critical components in various piping and construction applications, serving as flat surfaces for connecting pipes, valves, and other equipment. Their evolution reflects advancements in engineering, material science, and design, contributing to the efficiency and safety of

The Evolution of Flat Flanges in Building Materials

Introduction to Flat Flanges in the Construction Industry

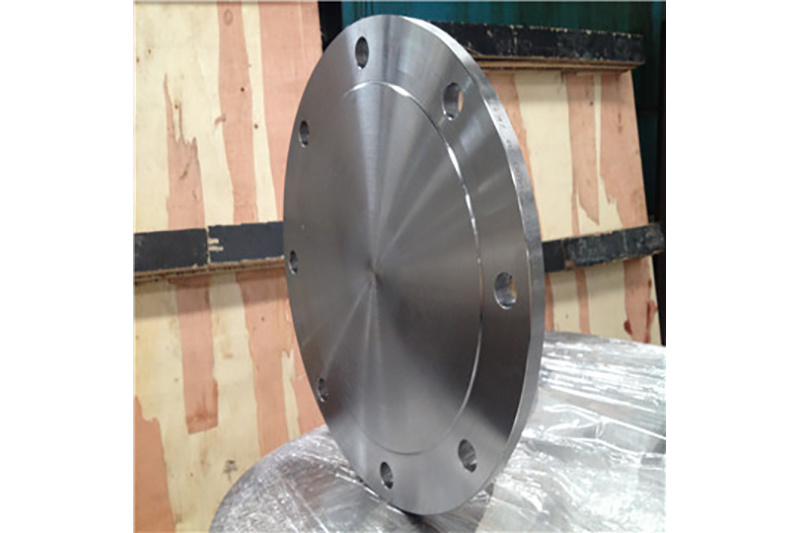

Flat flanges are critical components in various piping and construction applications, serving as flat surfaces for connecting pipes, valves, and other equipment. Their evolution reflects advancements in engineering, material science, and design, contributing to the efficiency and safety of modern structures.

Understanding Flat Flanges: Definition and Purpose

Flat flanges are circular, flat discs typically made from metal, plastic, or composite materials. They provide a surface for bolting or welding components together, ensuring secure connections in piping systems. The primary purpose of flat flanges is to facilitate the assembly and disassembly of piping networks, allowing for maintenance and modification without extensive deconstruction.

Historical Background of Flat Flanges

The use of flanges dates back to the early days of industrialization. Initially, flanges were rudimentary, made from basic materials and designed primarily for functionality. Over time, as industries grew and technologies advanced, the design and manufacturing processes for flat flanges evolved significantly.

Early Innovations in Flange Design

In the 19th century, the industrial revolution paved the way for innovative flange designs. Engineers began experimenting with different shapes and materials to enhance structural integrity and reliability. Early flanges were primarily cast iron or wrought steel, providing strength but limited flexibility in design.

Material Advancements that Shaped Flat Flanges

As technology progressed, so did the materials used in flange manufacturing. The introduction of stainless steel, aluminum, and composite materials revolutionized flange production, offering improved corrosion resistance, lighter weight, and greater strength.

The Role of Stainless Steel in Modern Flanges

Stainless steel became a preferred material due to its durability and resistance to rust and corrosion. This made it particularly useful in industries such as oil and gas, where exposure to harsh environments is common. The development of various stainless steel grades has allowed for flanges that can withstand high pressures and extreme temperatures.

Composite Materials: A New Frontier

The emergence of composite materials has also transformed flange design. These materials combine polymers with various additives, creating lightweight yet strong flanges. They are increasingly used in applications where traditional materials may fail due to weight constraints or corrosion.

Design Innovations in Flat Flanges

Recent years have seen a surge in design innovations aimed at improving the performance of flat flanges. These advancements are driven by the need for efficiency, safety, and sustainability in construction and manufacturing processes.

Standardization and the Rise of Metric Flanges

The globalization of industry led to the standardization of flange dimensions and specifications, particularly in metric systems. This standardization simplifies procurement and installation processes, ensuring compatibility across various systems worldwide.

Advanced Manufacturing Techniques

Modern manufacturing techniques, such as CNC machining and 3D printing, allow for greater precision in flange production. These methods reduce material waste and improve the overall quality of the final product, leading to enhanced performance in real-world applications.

Applications of Flat Flanges in Building Materials

Flat flanges are utilized across a spectrum of applications within the construction sector. Their versatility makes them indispensable in various systems, from plumbing and HVAC to fire protection and industrial piping.

Plumbing and HVAC Systems

In plumbing and heating, ventilation, and air conditioning (HVAC) systems, flat flanges are essential for connecting pipes and fixtures. Their ability to create leak-proof seals ensures reliable operation, reducing the chances of water damage or system failure.

Industrial Piping and Manufacturing

In industrial settings, flat flanges facilitate the assembly of complex piping systems. Their strength and durability are crucial in high-pressure environments, ensuring the safe transport of liquids and gases.

Fire Protection Systems

Flat flanges play a vital role in fire protection systems, connecting pipes for sprinkler systems and other fire suppression technologies. Their reliability is paramount in ensuring safety and compliance with fire codes.

Future Trends in Flat Flange Technology

As we look ahead, the future of flat flanges is shaped by trends toward sustainability, efficiency, and smart technologies.

The Shift Towards Sustainable Materials

With environmental considerations at the forefront of modern manufacturing, there is a growing emphasis on using sustainable materials in flange production. Innovations in biodegradable composites and recycled metals are set to transform the industry.

Smart Flanges and IoT Integration

The integration of IoT (Internet of Things) technologies into flange design is emerging as a game changer. Smart flanges equipped with sensors can monitor pressure, temperature, and other vital metrics, allowing for predictive maintenance and enhanced safety.

Best Practices for Selecting Flat Flanges

Choosing the right flat flange for a specific application requires careful consideration of several factors, including material, size, pressure rating, and compatibility with existing systems.

Assessing Material Compatibility

It's essential to select materials that are compatible with the fluids or gases being transported. For example, corrosive substances require flanges made from highly resistant materials like stainless steel or specialized composites.

Understanding Pressure Ratings

Always review the pressure ratings of flat flanges to ensure they can withstand operational demands. Choosing flanges rated for higher pressures than required can provide an extra layer of safety.

Consulting Industry Standards

Familiarity with industry standards, such as those set by ASTM and ASME, is vital for selecting the appropriate flanges. Compliance with these standards ensures safety and reliability in applications.

Common FAQs about Flat Flanges

1. What are the different types of flat flanges?

Flat flanges come in various types, including slip-on, blind, weld neck, and threaded flanges, each designed for specific applications.

2. How do I determine the right size of flat flange for my project?

The size of a flat flange is determined by the diameter of the pipe it will connect to, along with the pressure rating and application requirements.

3. Can flat flanges be reused?

In many cases, flat flanges can be reused if they are still in good condition. However, it's essential to inspect them for wear or damage before reinstallation.

4. What is the importance of flange gaskets?

Gaskets are crucial for creating a seal between flat flanges, preventing leaks and ensuring the integrity of the system.

5. How can I ensure the longevity of flat flanges?

To extend the lifespan of flat flanges, regular maintenance, proper installation, and the use of compatible materials are essential.

Conclusion

The evolution of flat flanges in building materials highlights significant advancements in design, materials, and applications. As industries continue to innovate, the future of flat flanges promises to be shaped by sustainability and technology. Understanding their development and significance is crucial for professionals in the construction and manufacturing sectors, ensuring efficient, safe, and reliable systems for years to come.

Latest developments

The Evolution of Flat Flanges in Building Materials: A Comprehensive Insight

The Evolution of Flat Flanges in Building Materials Introduction to Flat Flanges in the Construction Industry Flat flanges are critical components in various piping and construction applications, serving as flat surfaces for connecting pipes, valves, and other equipment. Their evolution reflects advancements in engineering, material science, and design, contributing to the efficiency and safety of

Understanding Steel Industries Forgings: Key Insights for Professionals

Steel industries forgings play a crucial role in the manufacturing of high-performance components that are integral to various sectors, particularly in construction and decorative materials. Forgings are produced by shaping metal through localized compressive forces, which can be applied through hammers or presses. This manufacturing process not only improves the mechanical properties of the steel

The Role of Forging in Enhancing Stainless Steel Properties: An In-Depth Exploration

The Role of Forging in Enhancing Stainless Steel Properties Table of Contents 1. Introduction to Stainless Steel and Forging 2. Overview of Forging Techniques 3. The Impact of Forging on Stainless Steel Properties 3.1 Enhancing Mechanical Strength 3.2 Improving Corrosion Resistance 3.3 Increasing Ductility and Toughness 4. Types of Forged Stainless Steel 5. Applications of Forged

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil