Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Release time:

2025-06-16

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we will delve into the details of threaded flanges and welded flanges, comparing their features, benefits, and applications to determine which option is best for your project.

Table of Contents

- Understanding Flanges: An Overview

- What Are Threaded Flanges?

- What Are Welded Flanges?

- Advantages of Threaded Flanges

- Advantages of Welded Flanges

- Disadvantages of Threaded Flanges

- Disadvantages of Welded Flanges

- Choosing the Right Flange for Your Project

- FAQs About Threaded and Welded Flanges

- Conclusion

Understanding Flanges: An Overview

Flanges are mechanical components used to connect pipes, valves, pumps, and other equipment within a piping system. They create a reliable and leak-proof joint that can withstand high pressure and temperature. The two common types of flanges, threaded and welded, serve distinct purposes and offer unique benefits suitable for different applications. Understanding the differences is crucial for ensuring the integrity and efficiency of your piping system.

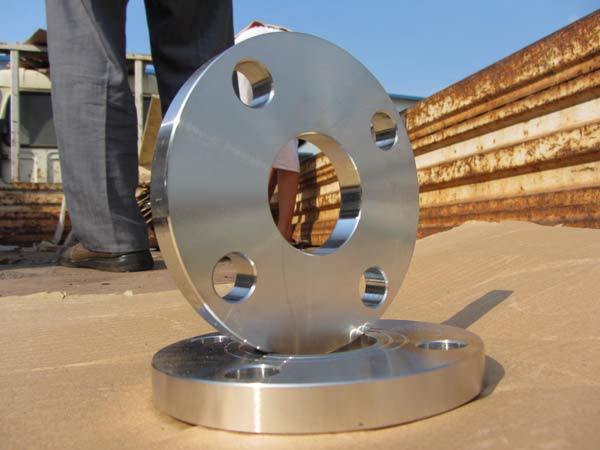

What Are Threaded Flanges?

Threaded flanges are designed with internal threads that allow them to be screwed onto pipes. This design offers a straightforward, secure connection without the need for welding. Threaded flanges are often used in systems where the risk of high temperature and pressure is minimal, as they are more susceptible to leakage compared to welded flanges. Common applications include:

- Low-pressure piping systems

- Water and sewage systems

- Gas distribution systems

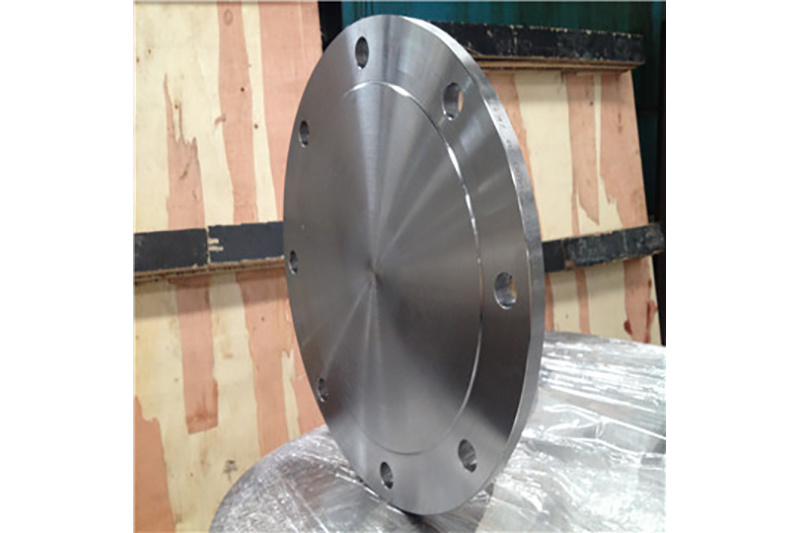

What Are Welded Flanges?

Welded flanges are permanently attached to pipes through welding. This type of flange provides a robust and secure connection, making it ideal for high-pressure applications where strength and reliability are critical. Welded flanges create a stronger bond than threaded flanges, significantly reducing the risk of leaks. They are widely used in:

- Petrochemical industries

- Oil and gas transportation

- Chemical processing plants

Advantages of Threaded Flanges

Threaded flanges have a number of notable advantages, making them suitable for certain applications:

1. Easy Installation

One of the primary benefits of threaded flanges is their ease of installation. They can be quickly screwed onto pipes without the need for specialized equipment or extensive training. This saves time and labor costs in many projects.

2. No Need for Welding

Since threaded flanges do not require welding, they can be beneficial in situations where heat needs to be minimized, such as in heat-sensitive materials. This also reduces the need for costly welding inspections.

3. Flexibility

Threaded flanges allow for quick disassembly and reassembly, making them ideal for temporary installations or systems that require frequent maintenance and adjustments.

Advantages of Welded Flanges

Welded flanges also provide a wide array of benefits:

1. Enhanced Strength

By creating a permanent connection, welded flanges offer superior strength and resistance to high pressure and temperature. This makes them the preferred choice for critical applications in industries such as oil and gas.

2. Leak Resistance

Welded flanges significantly reduce the risk of leaks due to their continuous connection. The welding process creates a solid bond that can withstand extreme conditions without compromising the integrity of the piping system.

3. Durability

Welded connections are generally more durable than threaded connections, making them less prone to wear and tear over time. This results in lower maintenance costs and longer service life for the system.

Disadvantages of Threaded Flanges

Despite their advantages, threaded flanges also have several drawbacks:

1. Reduced Strength

Threaded flanges are not designed to withstand high pressures, which makes them unsuitable for critical applications. Their inherent weakness can lead to failures in demanding environments.

2. Leakage Risks

The nature of the threaded connection can lead to leaks, especially when subjected to vibrations or thermal expansion. Proper installation and regular inspections are essential to mitigate this risk.

Disadvantages of Welded Flanges

While welded flanges are strong, they come with their own set of disadvantages:

1. Complexity of Installation

Welding requires skilled labor and special equipment, which can increase overall project costs and time. This complexity may be a barrier for smaller projects or installations.

2. Permanent Connection

Once welded, flanges cannot be easily disassembled. This can pose challenges during maintenance or replacement, potentially leading to additional downtime and costs.

Choosing the Right Flange for Your Project

When deciding between threaded flanges and welded flanges, several factors should guide your choice:

1. Application Requirements

Evaluate the specific requirements of your application, including pressure, temperature, and fluid type. For high-pressure systems or critical applications, welded flanges are generally the better choice.

2. Installation Considerations

Consider the installation environment and available resources. If skilled labor and welding equipment are not accessible, threaded flanges might be more practical.

3. Budget Constraints

Analyze your budget. While threaded flanges may have lower upfront costs, consider long-term maintenance and replacement costs associated with each option.

FAQs About Threaded and Welded Flanges

1. Can threaded flanges be used in high-pressure applications?

Threaded flanges are generally not recommended for high-pressure applications due to their lower strength compared to welded flanges.

2. What materials are commonly used for flanges?

Common materials for both threaded and welded flanges include stainless steel, carbon steel, and alloy steel, each selected based on the specific application requirements.

3. Are there any standards governing flange design and use?

Yes, various standards, such as ANSI, ASME, and ASTM, provide guidelines for flange design, materials, and testing to ensure safety and performance.

4. How do I maintain threaded flanges?

Regular inspections, ensuring proper torque during installation, and monitoring for signs of wear can help maintain threaded flanges effectively.

5. Is it possible to convert a threaded flange to a welded flange?

While it is technically possible to convert a threaded flange to a welded flange, it requires professional welding and proper preparation to ensure the integrity of the connection.

Conclusion

Choosing between threaded flanges and welded flanges ultimately depends on your specific project needs. Threaded flanges offer ease of installation and flexibility, making them suitable for low-pressure applications or temporary setups. On the other hand, welded flanges provide unmatched strength, durability, and leak resistance, making them the ideal choice for high-pressure and critical applications. By thoroughly evaluating your requirements, you can make an informed decision that ensures the success of your piping system. Whether you opt for the convenience of threaded flanges or the robust reliability of welded flanges, understanding the nuances of each will empower you to achieve optimal results in your construction and decoration projects.

Latest developments

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Understanding Flanged Connections in Construction and Decor Materials

Flanged connections are mechanical joints that consist of two flanges, bolted together to create a tight seal. These connections are essential in the construction and decorative materials industry, especially in plumbing and piping systems where fluid transport is critical. The choice of flanged connections can significantly affect the integrity and efficiency of piping systems, making it vital fo

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, a specialized type of flange, are designed with an extended neck that provides additional height. This design not only facilitates an increased surface area for welding but also assists in alignment, making them ideal for various applications in piping systems. The extended neck allows for a better connection to pipes and creates a more robust sealing surface, reducing the risk