The Connection Between Japanese Standard Flanges and Sustainable Construction

Release time:

2025-06-18

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

The Connection Between Japanese Standard Flanges and Sustainable Construction

Table of Contents

1. Understanding Japanese Standard Flanges

2. The Importance of Sustainable Construction

3. Key Features of Japanese Standard Flanges

3.1 Material Composition and Environmental Impact

3.2 Precision Engineering and Quality Assurance

4. How Japanese Standard Flanges Promote Sustainability

4.1 Energy Efficiency in Construction

4.2 Waste Reduction and Resource Conservation

5. Case Studies: Successful Sustainable Projects Using Japanese Standard Flanges

6. Future Trends in Flange Design and Sustainable Practices

7. Frequently Asked Questions

8. Conclusion

1. Understanding Japanese Standard Flanges

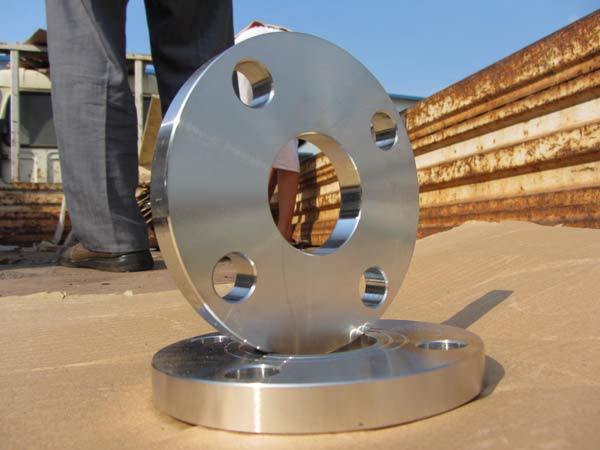

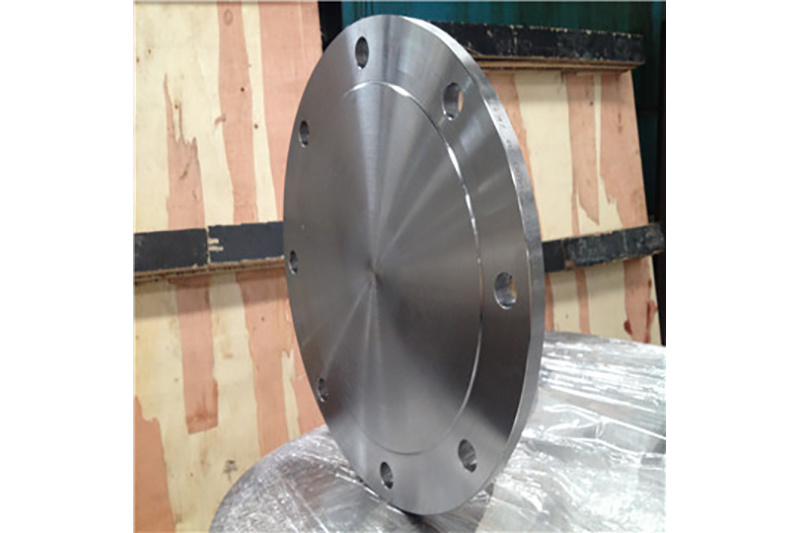

Japanese standard flanges are critical components used in piping and structural systems. They are designed according to specific standards set by organizations such as the Japanese Industrial Standards (JIS). These flanges provide a reliable means of connecting pipes, valves, and other equipment, ensuring a leak-proof and secure assembly. The precision in their design allows for optimal performance in various applications, from industrial to residential construction.

2. The Importance of Sustainable Construction

Sustainable construction emphasizes the use of eco-friendly materials and practices to minimize environmental impact. This approach not only conserves resources but also enhances the quality of life for future generations. As the world grapples with climate change and resource depletion, the construction industry plays a pivotal role in adopting sustainable practices. By integrating materials and methodologies that promote sustainability, we can significantly reduce our carbon footprint and create healthier living environments.

3. Key Features of Japanese Standard Flanges

Japanese standard flanges are characterized by several notable features that enhance their utility in construction projects.

3.1 Material Composition and Environmental Impact

These flanges are often made from high-quality steel or other alloys, contributing to their durability and resistance to corrosion. The choice of materials directly influences the sustainability of building projects. Flanges produced with lower carbon emissions and recyclable materials align with green building standards, reducing environmental impact.

3.2 Precision Engineering and Quality Assurance

The manufacturing process of Japanese standard flanges involves advanced techniques to ensure precision and quality. This high level of engineering results in flanges that meet rigorous safety and performance standards. The reliability of these components minimizes the risk of failures, which can lead to costly repairs and resource waste.

4. How Japanese Standard Flanges Promote Sustainability

Japanese standard flanges contribute to sustainable construction in various ways, enhancing both efficiency and environmental stewardship.

4.1 Energy Efficiency in Construction

The design of these flanges promotes optimal flow and minimizes turbulence in piping systems. This efficiency translates into lower energy consumption for heating, cooling, and transporting fluids. By reducing energy usage, construction projects utilizing Japanese standard flanges can significantly decrease their overall energy footprint.

4.2 Waste Reduction and Resource Conservation

Using Japanese standard flanges helps minimize material waste during construction. Their precise dimensions and compatibility with standardized systems reduce the need for custom fittings, leading to less scrap material. Additionally, the durability of these flanges means they have a longer lifespan, further decreasing the need for replacements and the associated resource expenditure.

5. Case Studies: Successful Sustainable Projects Using Japanese Standard Flanges

Numerous construction projects have successfully integrated Japanese standard flanges to enhance sustainability.

One notable example is the construction of a green office building in Tokyo that utilized these flanges in its plumbing and HVAC systems. By employing high-quality flanges that ensured efficient fluid transport, the building achieved a significant reduction in overall energy consumption. The project received accolades for its commitment to sustainable practices and served as a model for future developments.

6. Future Trends in Flange Design and Sustainable Practices

As sustainability remains a priority in the construction industry, trends in flange design are evolving. We can expect to see an increased focus on:

- **Recyclable Materials**: The development of flanges made from fully recyclable materials will play a crucial role in reducing waste.

- **Smart Technology Integration**: Incorporating sensors and monitoring systems into flange designs may enhance performance tracking and maintenance efficiency.

- **Enhanced Collaboration**: Greater collaboration between manufacturers and construction firms will lead to innovations that prioritize sustainability in flange design.

7. Frequently Asked Questions

1. What are Japanese standard flanges?

Japanese standard flanges are components used in piping systems, designed according to the Japanese Industrial Standards for optimal performance and reliability.

2. How do Japanese standard flanges contribute to sustainability?

They promote sustainability by enhancing energy efficiency, reducing material waste, and utilizing eco-friendly materials in their production.

3. What materials are used in the production of Japanese standard flanges?

These flanges are typically made from high-quality steel or alloys that provide durability and resistance to corrosion.

4. Can Japanese standard flanges be used in residential construction?

Yes, they are versatile and can be used in various applications, including residential plumbing and heating systems.

5. How do I ensure the quality of Japanese standard flanges for my project?

Choose flanges from reputable manufacturers that comply with JIS standards and have a track record of quality assurance in their production processes.

8. Conclusion

The connection between Japanese standard flanges and sustainable construction is significant and multifaceted. These components not only enhance the efficiency and reliability of piping systems but also contribute to the broader goals of environmental sustainability. By choosing high-quality, standardized flanges, construction professionals can reduce waste, conserve resources, and lower energy consumption, all while adhering to rigorous safety and performance standards. As we look toward the future, the ongoing evolution of flange design will undoubtedly continue to support the industry's shift toward more sustainable practices, ultimately benefiting both the environment and society as a whole.

Previous

Latest developments

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Understanding Flanged Connections in Construction and Decor Materials

Flanged connections are mechanical joints that consist of two flanges, bolted together to create a tight seal. These connections are essential in the construction and decorative materials industry, especially in plumbing and piping systems where fluid transport is critical. The choice of flanged connections can significantly affect the integrity and efficiency of piping systems, making it vital fo

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, a specialized type of flange, are designed with an extended neck that provides additional height. This design not only facilitates an increased surface area for welding but also assists in alignment, making them ideal for various applications in piping systems. The extended neck allows for a better connection to pipes and creates a more robust sealing surface, reducing the risk