Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Release time:

2025-06-14

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring that piping systems can adapt to changing conditions without compromising structural integrity. In this article, we will delve deeply into the world of sliding flanges, exploring their definition, functionality, benefits, applications, and installation methods in architectural contexts.

Table of Contents

- What Are Sliding Flanges?

- Benefits of Sliding Flanges in Pipe Systems

- Applications of Sliding Flanges in Architecture

- Design Considerations for Sliding Flanges

- Installation of Sliding Flanges: A Step-by-Step Guide

- Maintenance Tips for Sliding Flanges

- Common Issues with Sliding Flanges and Solutions

- Conclusion

What Are Sliding Flanges?

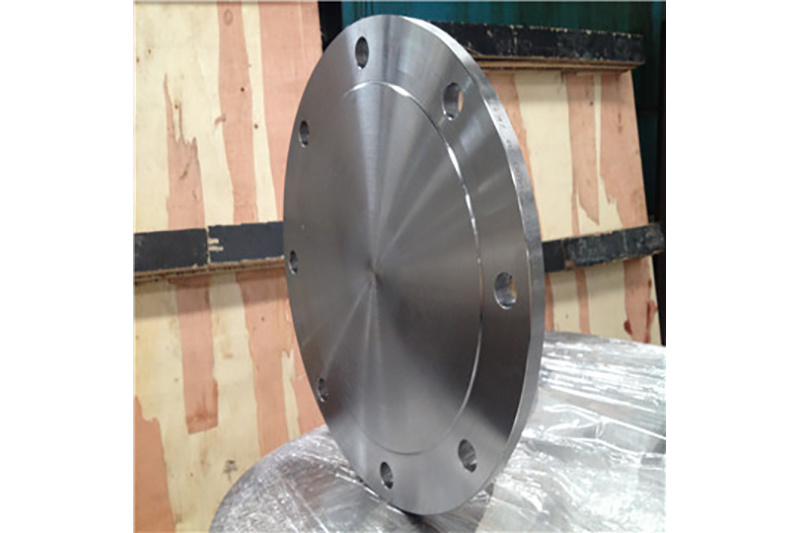

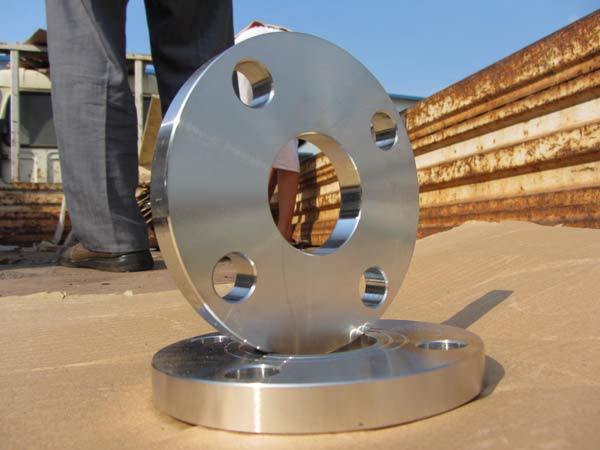

Sliding flanges are specialized components used in piping systems designed to provide a flexible connection between two sections of pipe. Unlike fixed flanges, which are rigidly secured and do not allow for movement, sliding flanges permit axial movement along the length of the pipe. This feature is particularly beneficial in systems where thermal expansion, contraction, or shifting of materials is expected. Typically made from durable materials such as stainless steel or carbon steel, sliding flanges come in various sizes and pressure ratings, making them suitable for diverse applications.

The Structure of Sliding Flanges

Sliding flanges are composed of several critical parts that work together to facilitate their functionality:

- Flange Body: The main component that connects to the pipe.

- Sliding Sleeve: Allows the flange to slide over the pipe, accommodating movement.

- Sealing Mechanism: Ensures a leak-proof connection, typically involving gaskets or O-rings.

- Bolting Pattern: The arrangement of bolts that secure the sliding flange to the corresponding fixed flange.

Benefits of Sliding Flanges in Pipe Systems

Utilizing sliding flanges in architectural pipe systems offers numerous advantages, including:

1. Enhanced Flexibility

Sliding flanges enable the movement of pipes without compromising the integrity of the joint. This adaptability is essential in environments subjected to thermal fluctuations.

2. Simplified Maintenance

With their ability to accommodate movement, sliding flanges reduce the stress on joints, minimizing wear and tear. This leads to lower maintenance costs over time.

3. Space Efficiency

Sliding flanges can be installed in tight spaces where traditional fixed flanges may not fit, making them ideal for complex architectural designs.

4. Improved System Longevity

By mitigating the risk of joint failure due to movement or stress, sliding flanges can significantly extend the lifespan of piping systems.

5. Easy Installation

Sliding flanges can be quickly installed and adjusted, allowing for efficient construction timelines and reduced labor costs.

Applications of Sliding Flanges in Architecture

Sliding flanges are employed in a variety of architectural applications, including:

1. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, sliding flanges accommodate the thermal expansion of ductwork and piping, ensuring optimal performance.

2. Water Supply and Distribution

Sliding flanges are widely used in water distribution systems, allowing for adjustments as the system settles or as temperature changes occur.

3. Industrial Applications

In industrial settings, sliding flanges are essential for connecting pipelines that transport liquids and gases, especially in environments with high temperature and pressure variations.

4. Fire Protection Systems

Fire suppression systems utilize sliding flanges to ensure that piping can move without compromising the system's effectiveness during expansion or contraction.

5. Utility Infrastructure

Utility companies incorporate sliding flanges in their pipeline systems to manage the challenges associated with ground movement and temperature fluctuations.

Design Considerations for Sliding Flanges

When incorporating sliding flanges into architectural designs, several factors must be considered:

1. Material Selection

Choosing the right material is crucial for durability and performance. Stainless steel is often preferred due to its corrosion resistance, while carbon steel is a cost-effective option for non-corrosive environments.

2. Pressure Ratings

Sliding flanges must be selected based on the pressure requirements of the system. Ensure that the flanges chosen can withstand the stresses they will encounter.

3. Gasket Selection

Utilizing the appropriate gasket material is vital for preventing leaks. Consider the fluid being transported and the temperature conditions when selecting gaskets.

4. Bolting Specifications

Ensure that the bolting pattern and torque specifications meet industry standards to avoid failures and maintain safety.

5. Thermal Expansion Considerations

Analyze the thermal expansion characteristics of the materials involved to determine the necessary length and movement allowance of the sliding flanges.

Installation of Sliding Flanges: A Step-by-Step Guide

Installing sliding flanges requires careful attention to detail to ensure a secure and functional connection. Here’s a step-by-step guide:

Step 1: Preparation

Before installation, ensure that the pipe ends are clean and free from debris. Check that the sliding flange and the fixed flange are compatible in size and type.

Step 2: Align the Flanges

Position the sliding flange onto the pipe, aligning it with the fixed flange. Ensure that the sliding sleeve is positioned correctly for optimal movement.

Step 3: Insert the Gasket

Place the gasket between the sliding flange and the fixed flange. Ensure that it fits snugly and provides a complete seal.

Step 4: Apply Bolts

Secure the flanges together using the appropriate bolts, following the specified torque values to prevent any leaks or failures.

Step 5: Test for Leaks

After installation, conduct a pressure test to check for leaks. If any leaks are detected, re-tighten the bolts and check the gasket placement.

Step 6: Monitor Movement

Observe the pipe system over time to ensure that the sliding flanges function correctly and accommodate movement as intended.

Maintenance Tips for Sliding Flanges

To ensure the longevity and performance of sliding flanges, regular maintenance is essential:

1. Regular Inspections

Conduct periodic inspections to check for signs of wear, corrosion, or leaks. Early detection can prevent more significant issues down the line.

2. Clean the Flanges

Keep sliding flanges clean to prevent buildup that could interfere with their movement. Use appropriate cleaning agents that won’t damage the materials.

3. Check Gasket Integrity

Inspect gaskets for signs of deterioration or damage. Replacing gaskets at the first signs of wear can prevent leaks and ensure a proper seal.

4. Tighten Bolts

Verify that the bolts are tightened to the manufacturer’s specified torque. Over time, vibrations and temperature fluctuations can loosen bolts, leading to leaks.

5. Monitor System Performance

Pay attention to the overall performance of the piping system. Any unusual changes in pressure or flow should be investigated promptly.

Common Issues with Sliding Flanges and Solutions

While sliding flanges are highly beneficial, they may encounter issues that require attention:

1. Leaks

Leaks are one of the most common issues with sliding flanges. To address this, ensure proper installation and regularly check the condition of gaskets and bolts.

2. Corrosion

Corrosion can compromise sliding flanges, particularly in harsh environments. Use corrosion-resistant materials and apply protective coatings where necessary.

3. Misalignment

Misalignment can lead to excessive wear and failure. Ensure that flanges are correctly aligned during installation and periodically check alignment as part of routine maintenance.

4. Thermal Expansion Issues

Improper allowances for thermal expansion can cause stress on the system. Calculate thermal expansion accurately and adjust the sliding flanges accordingly.

5. Wear and Tear

Over time, wear and tear can occur due to constant movement. Regularly inspect the sliding mechanisms and replace components as necessary to maintain functionality.

Conclusion

Sliding flanges play an indispensable role in the flexibility and efficiency of architectural pipe systems. Their ability to adapt to changing conditions while providing secure connections makes them invaluable in modern design and infrastructure. By understanding their benefits, applications, and proper maintenance, architects and engineers can create systems that meet the demands of today's dynamic environments. Investing in high-quality sliding flanges and ensuring their correct installation and care will undoubtedly enhance the longevity and reliability of piping systems in any architectural project.

Latest developments

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Understanding Flanged Connections in Construction and Decor Materials

Flanged connections are mechanical joints that consist of two flanges, bolted together to create a tight seal. These connections are essential in the construction and decorative materials industry, especially in plumbing and piping systems where fluid transport is critical. The choice of flanged connections can significantly affect the integrity and efficiency of piping systems, making it vital fo

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, a specialized type of flange, are designed with an extended neck that provides additional height. This design not only facilitates an increased surface area for welding but also assists in alignment, making them ideal for various applications in piping systems. The extended neck allows for a better connection to pipes and creates a more robust sealing surface, reducing the risk