Understanding Non-Standard Flanges: Essential Insights for Professionals in the Construction and Decoration Industry

Release time:

2025-06-29

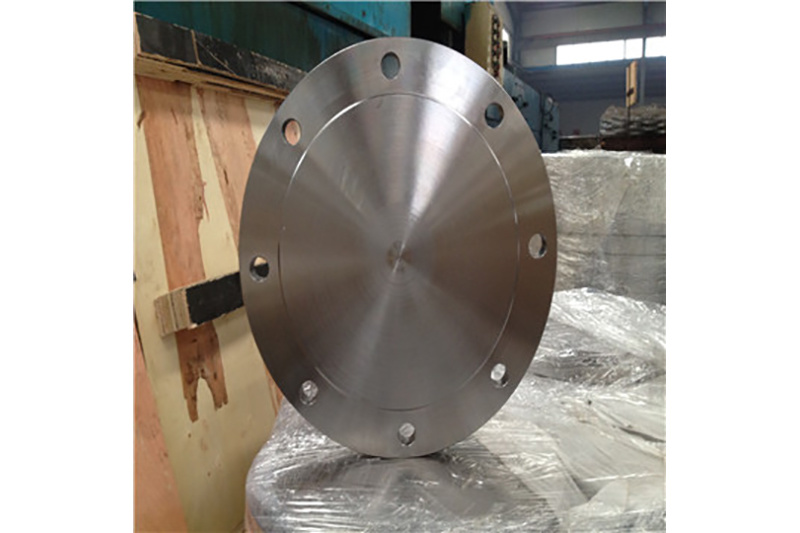

Non-standard flanges refer to flanges that do not conform to the typical sizes, shapes, or specifications established by industry standards such as ASTM or ASME. These specialized flanges are often designed to meet unique requirements in specific applications, making them a crucial component in various construction and pipefitting projects. One of the primary reasons for the use of non-standard f

One of the primary reasons for the use of non-standard flanges is the need for customization in specific construction scenarios. Each project may have unique demands based on design specifications, environmental conditions, or performance requirements. As such, non-standard flanges can be tailored to fit particular pipe dimensions, pressure ratings, or material types, ensuring optimal performance in their designated applications.

In many cases, industries such as oil and gas, power generation, and chemical processing require non-standard flanges to accommodate unconventional piping layouts or to connect different types of materials. For example, a non-standard flange might be required to connect a pipe made of steel to another made of plastic, necessitating a customized design to ensure a secure and leak-proof connection.

When selecting non-standard flanges, professionals should consider several factors. Firstly, the material composition of the flange is critical, as it must be compatible with the fluids or gases being transported. Additionally, the flange's design must account for the operating pressure and temperature conditions to ensure safety and reliability.

Another important consideration is the manufacturing process. Non-standard flanges may be produced through various methods, including forging, casting, or machining. Understanding the implications of each method can help you choose the best option for your specific application. It is also essential to ensure that the manufacturer has a proven track record of quality and precision in producing non-standard components.

While the use of non-standard flanges may involve additional planning and coordination, the benefits of tailored solutions often outweigh the challenges. These flanges not only enhance the functionality and integrity of piping systems but also contribute to the overall success of construction projects.

In conclusion, non-standard flanges serve a vital role in the construction and decoration materials industry. By recognizing their importance and understanding how to effectively utilize them, professionals can enhance their project outcomes. Always engage with knowledgeable suppliers and manufacturers to ensure you’re making the best choices for your specific needs.

Latest developments

Non-standard flanges refer to flanges that do not conform to the typical sizes, shapes, or specifications established by industry standards such as ASTM or ASME. These specialized flanges are often designed to meet unique requirements in specific applications, making them a crucial component in various construction and pipefitting projects. One of the primary reasons for the use of non-standard f

Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Maximizing Performance with Japanese Standard Flanges in Your Pipeline Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flanges: The Basics 3. Benefits of Japanese Standard Flanges 4. Applications of Japanese Standard Flanges in Various Industries 5. Selecting the Right Japanese Standard Flanges for Your Pipeline 6. Installation Tips for Japa

Understanding American Standard Flanges: Key Insights for Construction and Decoration Materials

American standard flanges are critical components in piping systems, particularly in the construction and decoration materials sector. They serve as connections between two sections of pipe, allowing for the secure assembly and disassembly of piping systems without compromising the integrity of the overall structure. Understanding the key attributes of American standard flanges can significantly e

Maintaining Your Threaded Flanges: Expert Tips for Longevity in Construction and Decoration

Maintaining Your Threaded Flanges: Tips for Longevity Table of Contents Understanding Threaded Flanges The Importance of Maintenance for Threaded Flanges Common Issues with Threaded Flanges and Their Solutions Best Practices for Maintaining Threaded Flanges Protective Coatings and Treatments for Threaded Flanges How to Inspect Threaded Flanges Effectively When to Repla

Understanding Flanged Connections: Essential Insights for Building and Decorative Materials

Flanged connections are a pivotal aspect of piping systems, specifically designed to join two sections of pipe or a pipe to a valve or fitting. These connections utilize flanges—flat pieces of material with holes for bolts—that create a secure seal between components. A properly executed flanged connection ensures the integrity and efficiency of fluid transport systems, making it an essential topi

Top 5 Advantages of Incorporating Sliding Flanges in Your Designs

Top 5 Advantages of Incorporating Sliding Flanges in Your Designs Introduction to Sliding Flanges In the world of construction and design materials, sliding flanges stand out as a crucial component that facilitates a variety of applications. These unique connections allow for flexibility in piping systems, making them indispensable in many industrial and architectural projects. Understanding the