Understanding High Neck Flanges: Essential Components in Construction and Decoration

Release time:

2025-07-03

High neck flanges play a pivotal role in the construction and decoration materials sector, especially in pipe fitting applications. These specialized flanges are characterized by their extended neck, which serves to enhance alignment and stability in piping systems. The design of high neck flanges allows for a smoother connection between pipes, minimizing the potential for leaks and ensuring a sec

One of the primary benefits of high neck flanges is their ability to provide a strong and reliable seal in high-pressure environments. With their added height, these flanges can accommodate thicker gaskets, which help to improve sealing performance. This is particularly important in systems where fluid movement is under high pressure, as any leakage can lead to significant safety hazards and operational inefficiencies.

In the context of construction, high neck flanges are often used in conjunction with various piping materials, including steel, PVC, and other composites. Their versatility makes them suitable for a wide range of applications, from plumbing systems in residential buildings to more complex industrial setups. The extended neck design allows for easier access during installation and maintenance, which is crucial in projects that require regular inspections.

Moreover, high neck flanges contribute to overall system integrity. Because they provide enhanced support for the piping structure, they help to prevent sagging or misalignment over time. This characteristic is especially beneficial in areas where piping systems are exposed to vibrations or stress, as it helps to maintain the long-term functionality of the installation.

Installation of high neck flanges typically requires careful alignment to ensure optimal performance. It is crucial to follow proper procedures and use appropriate tools when fitting these flanges to avoid any misalignment that could compromise the system. Additionally, when selecting high neck flanges, it is essential to consider the specific requirements of the project, such as pressure ratings, material compatibility, and environmental conditions.

In summary, high neck flanges are essential components in the construction and decoration materials industry, providing enhanced sealing and stability for piping systems. Their design features make them ideal for applications requiring reliability and efficiency, ensuring that fluid systems operate smoothly over time. Understanding the importance and functionality of high neck flanges can significantly contribute to the success of any construction project, making them a vital consideration for professionals in the field.

Previous

Previous

Latest developments

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges play a pivotal role in the construction and decoration materials sector, especially in pipe fitting applications. These specialized flanges are characterized by their extended neck, which serves to enhance alignment and stability in piping systems. The design of high neck flanges allows for a smoother connection between pipes, minimizing the potential for leaks and ensuring a sec

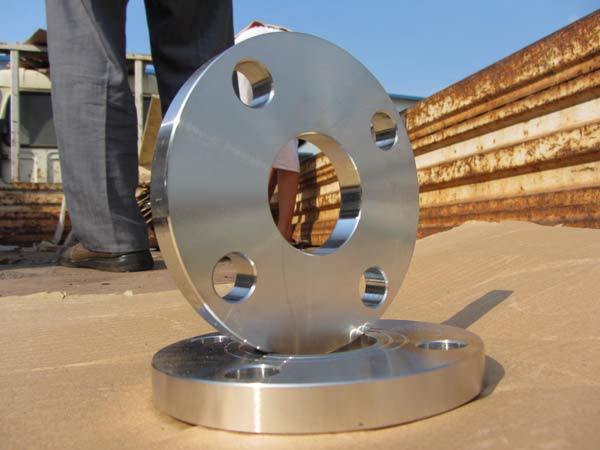

Flat Flanges: A Comprehensive Guide for Contractors

Flat Flanges: A Comprehensive Guide for Contractors Table of Contents 1. Introduction to Flat Flanges 2. What Are Flat Flanges? 3. Types of Flat Flanges 4. Materials Used in Flat Flanges 5. Applications of Flat Flanges in Construction 6. Installation and Maintenance of Flat Flanges 7. Cost Considerations for Contractors 8. Common Issues and Solutions with Flat Flan

Exploring the Role of Steel Industries Forgings in Construction and Decorative Materials

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength, durability, and aesthetic appeal to a variety of applications. Forgings are formed by the shaping of metal using localized compressive forces, and they are produced through several techniques, including hammering, pressing, and rolling. This process improves the grain structure of

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components Table of Contents Understanding Stainless Steel The Importance of Forging in Manufacturing Types of Forging Processes Step-by-Step Forging Process Post-Forging Treatments and Finishes Common Applications of Forged Stainless Steel Components Challenges in Forging Stainless Steel FAQs About

Non-standard flanges refer to flanges that do not conform to the typical sizes, shapes, or specifications established by industry standards such as ASTM or ASME. These specialized flanges are often designed to meet unique requirements in specific applications, making them a crucial component in various construction and pipefitting projects. One of the primary reasons for the use of non-standard f

Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Maximizing Performance with Japanese Standard Flanges in Your Pipeline Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flanges: The Basics 3. Benefits of Japanese Standard Flanges 4. Applications of Japanese Standard Flanges in Various Industries 5. Selecting the Right Japanese Standard Flanges for Your Pipeline 6. Installation Tips for Japa