Flanged Connections: The Unsung Heroes of Piping Systems

Release time:

2025-07-14

When you think about piping systems, flanged connections might not be the first thing that comes to mind. Yet, these simple but essential components are what keep everything securely linked—whether in a factory, a water treatment plant, or even a brewery. So, where exactly do flanged connections shine, and why should users care about choosing the right one? Let’s explore.

When you think about piping systems, flanged connections might not be the first thing that comes to mind. Yet, these simple but essential components are what keep everything securely linked—whether in a factory, a water treatment plant, or even a brewery. So, where exactly do flanged connections shine, and why should users care about choosing the right one? Let’s explore.

Where Flanged Connections Make a Difference

-

Easy Assembly and Disassembly

Unlike welded joints, flanged connections allow for quick installation and removal. Need to replace a valve or clean a pipe? Just unbolt the flange instead of cutting and rewelding. This saves time and effort, especially in maintenance-heavy industries. -

High-Pressure Handling

In oil and gas pipelines or steam systems, flanged connections provide a strong, leak-proof seal even under extreme pressure. A quality Flanged connection here means fewer risks of dangerous leaks or costly shutdowns. -

Flexibility in System Design

Flanges make it easy to connect different materials or adjust piping layouts. Whether it’s stainless steel meeting cast iron or adding a new branch line, flanged connections offer adaptability without major overhauls. -

Vibration Resistance

In machinery or pumping stations, pipes often vibrate. Flanged connections, especially when properly bolted, can handle this movement better than rigid welds, reducing wear and tear over time.

Choosing the Right Flanged Connection

Not all flanges are created equal. A cheap Flanged connection might seem like a good deal upfront, but if it fails under pressure or corrodes quickly, the repair costs can outweigh the initial savings. On the other hand, a well-made made in China flanged connection can offer both affordability and reliability if sourced from trusted suppliers.

For users, the decision often comes down to the application. Temporary setups or low-pressure systems might do fine with budget options. But for critical, long-term use—like in chemical plants or high-temperature steam lines—investing in a quality Flanged connection is a smarter move.

Final Thoughts

Flanged connections might not be glamorous, but they’re the backbone of many piping systems. Their versatility, strength, and ease of use make them indispensable across industries. Whether you opt for a cost-effective solution or a premium one, picking the right flange ensures smoother operations and fewer headaches down the line. After all, a secure connection today means fewer leaks tomorrow.

Latest developments

The Importance of Threaded Flanges in Plumbing Applications

The Importance of Threaded Flanges in Plumbing Applications Table of Contents 1. Understanding Threaded Flanges 2. Types of Threaded Flanges 3. Key Benefits of Using Threaded Flanges 3.1 Enhanced Connection Integrity 3.2 Ease of Installation and Maintenance 3.3 Versatility in Applications 4. Installation Techniques for Threaded Flanges 4.1 Preparing the Pipe Ends 4.2 Ensuring P

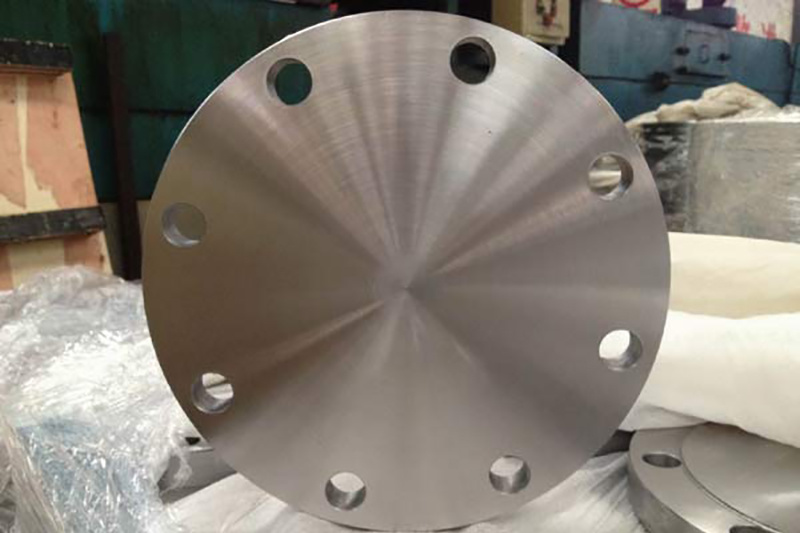

Blind Flanges: Where and Why They Matter in Everyday Piping Systems

When it comes to piping systems, one component that often goes unnoticed but plays a crucial role is the Blind flange. These simple yet effective discs are used to seal off the end of a pipe, valve, or vessel, ensuring safety and preventing leaks. But where exactly are they used, and why should users care about choosing the right one—whether it’s a quality Blind flange or a more cheap Blind flange option? Let’s break it down.

Flanged Connections: The Unsung Heroes of Piping Systems

When you think about piping systems, flanged connections might not be the first thing that comes to mind. Yet, these simple but essential components are what keep everything securely linked—whether in a factory, a water treatment plant, or even a brewery. So, where exactly do flanged connections shine, and why should users care about choosing the right one? Let’s explore.

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges are specialized components commonly used in the construction and decoration materials industry, particularly in the realm of piping and fittings. These flanges are characterized by their extended neck, which provides added height and a robust sealing surface. This unique design feature not only enhances their structural integrity but also facilitates easier alignment and installa

Sustainability in Construction: The Case for Flat Flanges

Sustainability in Construction: The Case for Flat Flanges Table of Contents Introduction to Sustainability in Construction The Importance of Sustainability in the Construction Industry What are Flat Flanges? Benefits of Using Flat Flanges in Sustainable Construction Material Sourcing: Eco-Friendly Options for Flat Flanges Energy Efficiency: How Flat Flanges Contribute Cost-Effec

Understanding the Role of Steel Forgings in the Construction Industry

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength and reliability to various structural applications. Forging is a manufacturing process that involves shaping metal using compressive forces, which can be delivered through hammers or presses. This process results in a product that is notably stronger and more durable than its non-f