Sustainability in Construction: The Case for Flat Flanges

Release time:

2025-07-12

Sustainability in Construction: The Case for Flat Flanges Table of Contents Introduction to Sustainability in Construction The Importance of Sustainability in the Construction Industry What are Flat Flanges? Benefits of Using Flat Flanges in Sustainable Construction Material Sourcing: Eco-Friendly Options for Flat Flanges Energy Efficiency: How Flat Flanges Contribute Cost-Effec

Sustainability in Construction: The Case for Flat Flanges

Table of Contents

- Introduction to Sustainability in Construction

- The Importance of Sustainability in the Construction Industry

- What are Flat Flanges?

- Benefits of Using Flat Flanges in Sustainable Construction

- Material Sourcing: Eco-Friendly Options for Flat Flanges

- Energy Efficiency: How Flat Flanges Contribute

- Cost-Effectiveness of Flat Flanges in Construction Projects

- Case Studies: Successful Implementation of Flat Flanges

- The Future of Flat Flanges in Sustainable Construction

- Frequently Asked Questions

- Conclusion

Introduction to Sustainability in Construction

In today’s rapidly evolving world, **sustainability** has emerged as a critical consideration across various sectors, particularly in construction. The construction industry is known for its significant environmental footprint, resulting from energy consumption, resource depletion, and waste generation. As we aim for a more sustainable future, it becomes imperative to **employ strategies and materials** that minimize these impacts. A notable solution in this regard is the use of **flat flanges**—a component that has gained attention for its versatility and environmental benefits.

The Importance of Sustainability in the Construction Industry

Sustainability in construction refers to the practice of creating structures that are environmentally responsible, resource-efficient, and economically viable. By focusing on sustainable practices, the industry can help to mitigate climate change, reduce carbon emissions, and conserve natural resources. Key aspects include:

Environmental Responsibility

Building sustainably means choosing materials and processes that have a minimal impact on the environment. This involves reducing waste, recycling materials, and ensuring energy-efficient processes.

Economic Viability

Sustainable construction practices often lead to cost savings in the long term. By investing in energy-efficient materials and methods, projects can benefit from lower operational costs and more reliable investments.

Social Equity

Sustainability also encompasses social aspects, ensuring that construction practices do not adversely affect communities. This includes providing safe and healthy building environments.

What are Flat Flanges?

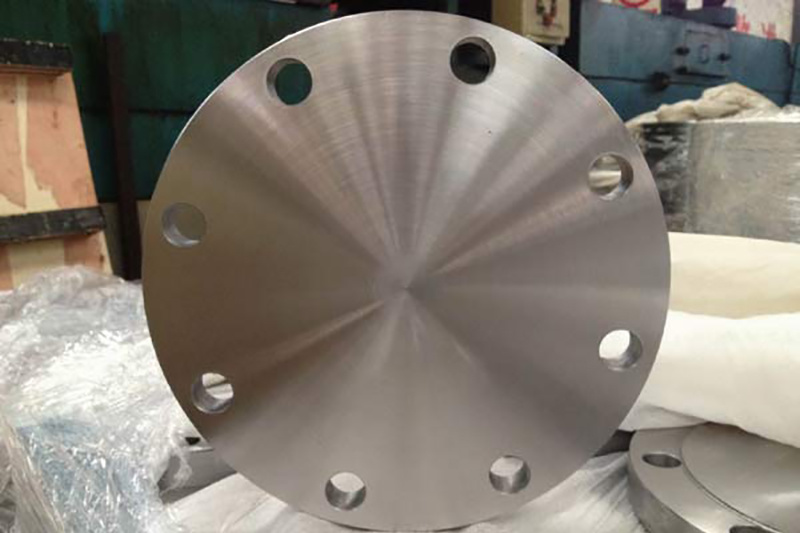

Flat flanges are **hardware components** that connect pipes, valves, pumps, and other equipment in various systems. They are designed to provide a robust sealing solution while allowing for easy access during installation and maintenance. Unlike traditional flanges, flat flanges feature a smooth, flat surface, which can offer advantages in terms of sealing performance and compatibility with various joinery methods.

Composition of Flat Flanges

Flat flanges can be crafted from various materials, including stainless steel, carbon steel, and plastic. The choice of material significantly impacts their **sustainability** profile, as some options are more eco-friendly than others.

Benefits of Using Flat Flanges in Sustainable Construction

The incorporation of flat flanges in construction projects presents several advantages that align with sustainability goals:

1. Enhanced Sealing Performance

Flat flanges provide superior sealing capabilities, reducing the risk of leaks. This not only conserves resources but also minimizes the potential for environmental contamination.

2. Reduced Waste

The design of flat flanges promotes **efficient use of materials**. They can be manufactured to precise specifications, resulting in less scrap material during production.

3. Longevity and Durability

Constructed to withstand harsh conditions, flat flanges tend to have a longer lifespan. This durability reduces the need for replacements, further decreasing resource consumption and waste.

4. Versatility in Applications

Flat flanges can be adapted for various applications across industries, making them a versatile choice in construction. Their compatibility with different materials allows for integration into numerous systems.

5. Ease of Maintenance

Flat flanges simplify maintenance processes, facilitating easy disassembly for repairs or upgrades. This aspect promotes sustainability by extending the lifespan of the entire system.

Material Sourcing: Eco-Friendly Options for Flat Flanges

Selecting the right materials for flat flanges is crucial for maximizing their sustainability benefits. Here are some eco-friendly options:

1. Recycled Materials

Using recycled metals for manufacturing flat flanges significantly lessens the environmental impact. Recycled metals require less energy to produce compared to virgin materials.

2. Sustainable Manufacturing Processes

Opt for manufacturers that utilize **green practices** during production, such as energy-efficient techniques and waste reduction strategies.

3. Certification and Standards

Look for materials that meet sustainability certifications, such as LEED (Leadership in Energy and Environmental Design), to ensure compliance with environmentally friendly guidelines.

Energy Efficiency: How Flat Flanges Contribute

Flat flanges can enhance energy efficiency in several ways:

1. Improved System Performance

Their superior sealing properties help maintain optimal system performance, reducing energy loss caused by leaks.

2. Compatibility with Energy-Efficient Systems

Flat flanges can be integrated into various energy-efficient systems, such as solar water heating and heating, ventilation, and air conditioning (HVAC) systems, maximizing overall efficiency.

Cost-Effectiveness of Flat Flanges in Construction Projects

While the initial investment in flat flanges may be higher than traditional alternatives, the long-term savings can be substantial:

1. Lower Maintenance Costs

The durability and ease of maintenance associated with flat flanges can lead to reduced maintenance costs over time.

2. Energy Savings

By preventing leaks and enhancing system performance, flat flanges can contribute to significant energy savings, which translates to lower utility bills.

Case Studies: Successful Implementation of Flat Flanges

Several construction projects have successfully integrated flat flanges, showcasing their advantages:

1. Eco-Friendly Office Building

A recent office building project utilized flat flanges in its plumbing and HVAC systems. The result was reduced energy consumption and improved indoor air quality, contributing to its LEED Gold certification.

2. Sustainable Industrial Facility

An industrial facility adopted flat flanges in their manufacturing processes, which led to a noticeable decrease in waste and enhanced operational efficiency.

The Future of Flat Flanges in Sustainable Construction

As the construction industry continues to evolve towards sustainability, the role of flat flanges is expected to expand. Ongoing research and innovation in materials and manufacturing processes promise to enhance their performance and eco-friendliness further. The future will likely see:

1. Advanced Materials

The development of new materials that are both sustainable and high-performing will elevate the efficacy of flat flanges.

2. Broader Industry Adoption

As awareness of sustainability in construction grows, more industries will likely adopt flat flanges as a standard component in their systems.

Frequently Asked Questions

1. What are the primary benefits of using flat flanges in construction?

Flat flanges offer enhanced sealing performance, reduced waste, increased durability, and versatility across various applications.

2. How do flat flanges improve energy efficiency?

Their superior sealing capabilities prevent leaks and ensure optimal system performance, leading to energy savings.

3. Are flat flanges environmentally friendly?

Yes, especially when made from recycled materials and produced through sustainable manufacturing processes.

4. Can flat flanges be used in various systems?

Absolutely! Flat flanges are compatible with a wide range of systems, including plumbing, HVAC, and industrial applications.

5. What should I consider when selecting flat flanges for my project?

Consider the material, sustainability certifications, and compatibility with your specific application to ensure the best performance and environmental impact.

Conclusion

Incorporating **flat flanges** into construction projects is a strategic move towards enhancing sustainability in the industry. Their myriad benefits, including improved sealing, reduced waste, and energy efficiency, make them a valuable component in modern construction practices. As we continue to seek solutions that align with environmentally responsible methods, flat flanges stand out as a beacon of innovation and practicality. Embracing such advancements not only supports the immediate needs of construction but also contributes to a more sustainable future for generations to come.

Latest developments

The Importance of Threaded Flanges in Plumbing Applications

The Importance of Threaded Flanges in Plumbing Applications Table of Contents 1. Understanding Threaded Flanges 2. Types of Threaded Flanges 3. Key Benefits of Using Threaded Flanges 3.1 Enhanced Connection Integrity 3.2 Ease of Installation and Maintenance 3.3 Versatility in Applications 4. Installation Techniques for Threaded Flanges 4.1 Preparing the Pipe Ends 4.2 Ensuring P

Blind Flanges: Where and Why They Matter in Everyday Piping Systems

When it comes to piping systems, one component that often goes unnoticed but plays a crucial role is the Blind flange. These simple yet effective discs are used to seal off the end of a pipe, valve, or vessel, ensuring safety and preventing leaks. But where exactly are they used, and why should users care about choosing the right one—whether it’s a quality Blind flange or a more cheap Blind flange option? Let’s break it down.

Flanged Connections: The Unsung Heroes of Piping Systems

When you think about piping systems, flanged connections might not be the first thing that comes to mind. Yet, these simple but essential components are what keep everything securely linked—whether in a factory, a water treatment plant, or even a brewery. So, where exactly do flanged connections shine, and why should users care about choosing the right one? Let’s explore.

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges are specialized components commonly used in the construction and decoration materials industry, particularly in the realm of piping and fittings. These flanges are characterized by their extended neck, which provides added height and a robust sealing surface. This unique design feature not only enhances their structural integrity but also facilitates easier alignment and installa

Sustainability in Construction: The Case for Flat Flanges

Sustainability in Construction: The Case for Flat Flanges Table of Contents Introduction to Sustainability in Construction The Importance of Sustainability in the Construction Industry What are Flat Flanges? Benefits of Using Flat Flanges in Sustainable Construction Material Sourcing: Eco-Friendly Options for Flat Flanges Energy Efficiency: How Flat Flanges Contribute Cost-Effec

Understanding the Role of Steel Forgings in the Construction Industry

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength and reliability to various structural applications. Forging is a manufacturing process that involves shaping metal using compressive forces, which can be delivered through hammers or presses. This process results in a product that is notably stronger and more durable than its non-f