Understanding American Standard Flanges: Key Features and Applications

Release time:

2025-07-07

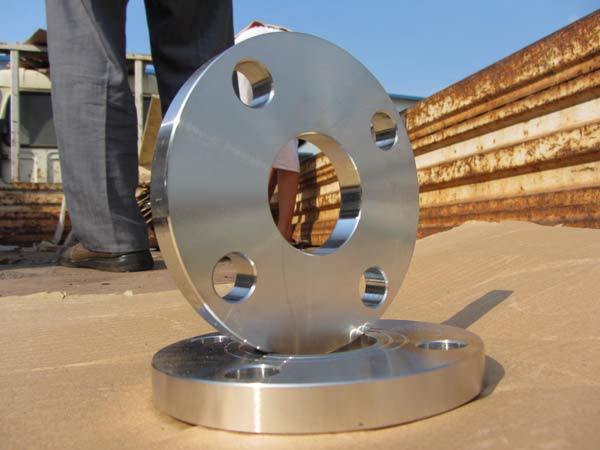

American Standard flanges are critical components used in a variety of piping systems, particularly within the construction and decorative materials sector. Designed to provide a reliable connection between pipes, valves, and other equipment, these flanges operate by creating a seal that prevents leaks and maintains pressure within the system. Understanding the specifications and applications of A

One of the defining characteristics of American Standard flanges is their adherence to specific dimensional standards, which are crucial for ensuring compatibility across different systems. Typically, these flanges are classified based on their dimensions, pressure ratings, and materials. The most common material used for manufacturing American Standard flanges is carbon steel, although they can also be found in stainless steel, plastic, and other materials depending on the specific requirements of the application.

When selecting an American Standard flange, it's essential to consider the size and pressure rating that best fits your project's needs. These flanges come in various sizes, from small-diameter options suitable for residential applications to larger models designed for industrial use. The pressure rating indicates the maximum pressure that the flange can handle, which is vital for applications involving high-pressure systems.

In addition to size and pressure ratings, the design of American Standard flanges plays a significant role in their functionality. Options such as slip-on, weld neck, and blind flanges each have unique advantages depending on the installation environment. For instance, slip-on flanges are often easier to install and are versatile for different piping configurations, while weld neck flanges are preferred for critical applications due to their ability to handle higher stresses.

The installation process for American Standard flanges requires careful attention to detail. Proper alignment and the use of appropriate gaskets are essential to ensure a tight seal that prevents leakage. Furthermore, understanding the torque specifications for the bolts used in the flange connection is crucial to achieving optimal performance and safety.

In summary, American Standard flanges are indispensable components in the construction and decorative materials industry, particularly in piping systems. Their standardized dimensions, material options, and various designs make them suitable for a wide range of applications. By understanding the key features and installation practices associated with these flanges, industry professionals can ensure that their projects are completed with efficiency and reliability.

Previous

Latest developments

Understanding American Standard Flanges: Key Features and Applications

American Standard flanges are critical components used in a variety of piping systems, particularly within the construction and decorative materials sector. Designed to provide a reliable connection between pipes, valves, and other equipment, these flanges operate by creating a seal that prevents leaks and maintains pressure within the system. Understanding the specifications and applications of A

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide Table of Contents 1. Introduction to Threaded Flanges 2. Importance of Material Selection for Threaded Flanges 3. Common Materials Used for Threaded Flanges 3.1 Carbon Steel Flanges 3.2 Stainless Steel Flanges 3.3 Duplex Steel Flanges 3.4 Alloy Steel

Understanding Flanged Connections: A Key Component in Building and Decorative Materials

Flanged connections are integral components widely used in piping systems, particularly within the construction and decorative materials sector. These connections enable the joining of pipes, valves, pumps, and other equipment, ensuring a reliable and leak-proof assembly. The design of a flanged connection typically consists of two flanges facing each other, which are bolted together with a gasket

Mastering Installation Techniques for Sliding Flanges in the Field

Mastering Installation Techniques for Sliding Flanges in the Field Table of Contents Introduction to Sliding Flanges Understanding Sliding Flanges and Their Applications Essential Tools for Sliding Flange Installation Preparation Steps for Flange Installation Step-by-Step Installation Process for Sliding Flanges Common Mistakes to Avoid During Installation Maintenance

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges play a pivotal role in the construction and decoration materials sector, especially in pipe fitting applications. These specialized flanges are characterized by their extended neck, which serves to enhance alignment and stability in piping systems. The design of high neck flanges allows for a smoother connection between pipes, minimizing the potential for leaks and ensuring a sec

Flat Flanges: A Comprehensive Guide for Contractors

Flat Flanges: A Comprehensive Guide for Contractors Table of Contents 1. Introduction to Flat Flanges 2. What Are Flat Flanges? 3. Types of Flat Flanges 4. Materials Used in Flat Flanges 5. Applications of Flat Flanges in Construction 6. Installation and Maintenance of Flat Flanges 7. Cost Considerations for Contractors 8. Common Issues and Solutions with Flat Flan