Flat Flanges: A Comprehensive Guide for Contractors

Release time:

2025-07-02

Flat Flanges: A Comprehensive Guide for Contractors Table of Contents 1. Introduction to Flat Flanges 2. What Are Flat Flanges? 3. Types of Flat Flanges 4. Materials Used in Flat Flanges 5. Applications of Flat Flanges in Construction 6. Installation and Maintenance of Flat Flanges 7. Cost Considerations for Contractors 8. Common Issues and Solutions with Flat Flan

Flat Flanges: A Comprehensive Guide for Contractors

Table of Contents

- 1. Introduction to Flat Flanges

- 2. What Are Flat Flanges?

- 3. Types of Flat Flanges

- 4. Materials Used in Flat Flanges

- 5. Applications of Flat Flanges in Construction

- 6. Installation and Maintenance of Flat Flanges

- 7. Cost Considerations for Contractors

- 8. Common Issues and Solutions with Flat Flanges

- 9. Conclusion

- 10. FAQs About Flat Flanges

1. Introduction to Flat Flanges

In the construction and decorative industry, the use of flat flanges has become increasingly prevalent due to their versatility and reliability. As contractors, understanding the various aspects of flat flanges can significantly enhance your project outcomes. This comprehensive guide will delve into the definition, types, materials, applications, installation, maintenance, and common issues associated with flat flanges, providing you with the insights needed to make informed decisions.

2. What Are Flat Flanges?

Flat flanges are circular pieces of material, typically made from metal or plastic, that serve as a connection point between two sections of piping or machinery. They provide a secure and stable joint by allowing for the easy assembly and disassembly of parts. Flat flanges are characterized by their smooth, flat surfaces, which facilitate a tight seal when joined with gaskets or other sealing materials.

Understanding Flange Standards

The industry has established various standards for flat flanges, including ANSI, ASME, and DIN. Each standard dictates the dimensions, material specifications, and pressure ratings that flanges must conform to, ensuring compatibility and safety in applications.

3. Types of Flat Flanges

Contractors should be familiar with the different types of flat flanges to select the most appropriate one for their projects.

Slip-On Flanges

Slip-on flanges are designed to slip over the end of a pipe. They are easier to align and weld compared to other types, making them a popular choice for contractors. However, they do require sufficient welding to ensure a strong joint.

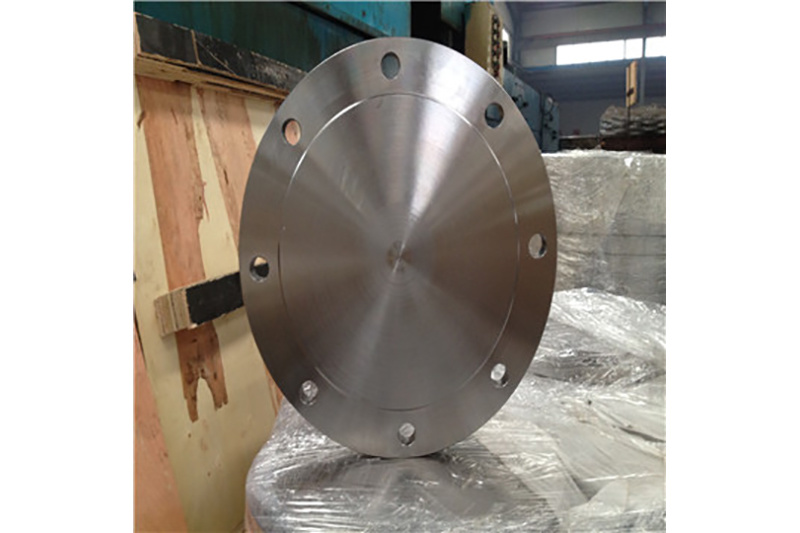

Blind Flanges

Blind flanges are solid disks that are used to seal the end of a pipe. They are essential for maintenance and pressure testing processes, as they allow for easy access to the piping system when needed.

Weld Neck Flanges

Weld neck flanges have a long neck that allows for a gradual transition into the pipe. This design minimizes stress concentration and is ideal for high-pressure applications, making them a preferred choice for critical systems.

Socket Weld Flanges

Socket weld flanges are designed for use with pipes that are smaller in diameter. The pipe fits directly into the flange, creating a strong and secure connection suitable for high-pressure applications.

4. Materials Used in Flat Flanges

Choosing the right material for flat flanges is crucial for ensuring durability and performance. Common materials include:

Carbon Steel

Carbon steel is a widely used material for flat flanges due to its strength and affordability. It is suitable for low to medium-pressure applications.

Stainless Steel

Stainless steel flanges offer excellent corrosion resistance, making them ideal for applications in harsh environments or where hygiene is a concern.

Plastic

Plastic flanges, such as PVC or CPVC, are lightweight and resistant to corrosion. They are predominantly used in chemical and wastewater applications.

5. Applications of Flat Flanges in Construction

Flat flanges find extensive applications across various sectors, including:

Piping Systems

In piping systems, flat flanges connect pipes, valves, and equipment, ensuring a leak-proof and secure system.

HVAC Systems

In HVAC systems, flat flanges are used to connect ductwork and air handling units, facilitating efficient airflow and temperature control.

Marine Applications

Marine environments require components that can withstand harsh conditions. Flat flanges made from corrosion-resistant materials are essential for shipbuilding and maintenance.

6. Installation and Maintenance of Flat Flanges

Proper installation and maintenance are vital for ensuring the longevity and effectiveness of flat flanges.

Installation Guidelines

1. **Surface Preparation**: Ensure that both the flange and the pipe surfaces are clean and free of debris.

2. **Gasket Placement**: Use the correct gasket material and size for the application, ensuring it is placed accurately between the flanges.

3. **Alignment**: Align the flanges properly to avoid stress on the bolts and ensure a tight seal.

4. **Bolt Tightening**: Tighten the bolts in a crisscross pattern to distribute pressure evenly, which helps achieve a secure connection.

Maintenance Tips

- Regularly inspect flanges for signs of wear, corrosion, or leaks.

- Re-torque bolts periodically, especially in high-pressure applications.

- Replace gaskets as necessary to maintain a proper seal.

7. Cost Considerations for Contractors

When budgeting for flat flanges, several factors influence costs:

Material Costs

Different materials come with varying price points. For instance, stainless steel flanges tend to be more expensive than carbon steel due to their superior corrosion resistance.

Labor Costs

Installation complexity affects labor costs. More intricate flange types, such as weld neck flanges, may require specialized skills and equipment, impacting overall project expenses.

Long-Term Value

Investing in high-quality flat flanges can lead to lower maintenance costs and reduced downtime, offering better long-term value despite a higher upfront cost.

8. Common Issues and Solutions with Flat Flanges

Contractors may encounter several challenges when working with flat flanges:

Leakage

**Issue**: Leakage can occur due to improper installation or gasket failure.

**Solution**: Ensure that gaskets are properly sized and positioned, and re-torque bolts if necessary.

Corrosion

**Issue**: Corrosion can weaken flanges, especially in harsh environments.

**Solution**: Use corrosion-resistant materials and apply protective coatings where necessary.

Misalignment

**Issue**: Misalignment can lead to stress and potential failure.

**Solution**: Always ensure proper alignment during installation and use alignment tools if needed.

9. Conclusion

Understanding flat flanges is essential for contractors looking to enhance the reliability and effectiveness of their projects. By knowing the different types of flanges, their materials, applications, and best practices for installation and maintenance, contractors can make informed decisions that lead to successful project outcomes. Whether working on piping systems, HVAC installations, or specialized applications, flat flanges play a pivotal role in ensuring project integrity. Always remember to consider the specific requirements of your project to choose the right flat flange for optimal performance.

10. FAQs About Flat Flanges

What is the primary function of flat flanges?

Flat flanges primarily serve as connection points between pipes and equipment, ensuring a secure and leak-proof joint.

How do I choose the right flange type for my project?

Consider the specific application, pressure requirements, and material compatibility when selecting a flange type.

What are the most common materials used for flat flanges?

Common materials for flat flanges include carbon steel, stainless steel, and various plastics such as PVC.

How do I maintain flat flanges?

Regular inspections, re-torquing bolts, and replacing gaskets as needed are essential maintenance practices for flat flanges.

Can flat flanges be reused?

Flat flanges can often be reused if they are in good condition and not damaged during disassembly. However, gaskets should always be replaced.

Previous

Latest developments

Flat Flanges: A Comprehensive Guide for Contractors

Flat Flanges: A Comprehensive Guide for Contractors Table of Contents 1. Introduction to Flat Flanges 2. What Are Flat Flanges? 3. Types of Flat Flanges 4. Materials Used in Flat Flanges 5. Applications of Flat Flanges in Construction 6. Installation and Maintenance of Flat Flanges 7. Cost Considerations for Contractors 8. Common Issues and Solutions with Flat Flan

Exploring the Role of Steel Industries Forgings in Construction and Decorative Materials

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength, durability, and aesthetic appeal to a variety of applications. Forgings are formed by the shaping of metal using localized compressive forces, and they are produced through several techniques, including hammering, pressing, and rolling. This process improves the grain structure of

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components Table of Contents Understanding Stainless Steel The Importance of Forging in Manufacturing Types of Forging Processes Step-by-Step Forging Process Post-Forging Treatments and Finishes Common Applications of Forged Stainless Steel Components Challenges in Forging Stainless Steel FAQs About

Non-standard flanges refer to flanges that do not conform to the typical sizes, shapes, or specifications established by industry standards such as ASTM or ASME. These specialized flanges are often designed to meet unique requirements in specific applications, making them a crucial component in various construction and pipefitting projects. One of the primary reasons for the use of non-standard f

Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Maximizing Performance with Japanese Standard Flanges in Your Pipeline Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flanges: The Basics 3. Benefits of Japanese Standard Flanges 4. Applications of Japanese Standard Flanges in Various Industries 5. Selecting the Right Japanese Standard Flanges for Your Pipeline 6. Installation Tips for Japa

Understanding American Standard Flanges: Key Insights for Construction and Decoration Materials

American standard flanges are critical components in piping systems, particularly in the construction and decoration materials sector. They serve as connections between two sections of pipe, allowing for the secure assembly and disassembly of piping systems without compromising the integrity of the overall structure. Understanding the key attributes of American standard flanges can significantly e