Exploring the Role of Steel Industries Forgings in Construction and Decorative Materials

Release time:

2025-07-01

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength, durability, and aesthetic appeal to a variety of applications. Forgings are formed by the shaping of metal using localized compressive forces, and they are produced through several techniques, including hammering, pressing, and rolling. This process improves the grain structure of

One of the primary advantages of using steel forgings is their ability to withstand high stress and fatigue levels. In construction, components such as beams, columns, and brackets made from forged steel can support significant loads and resist deformation over time. This is particularly important in high-rise buildings and infrastructure where structural integrity is paramount. Additionally, the enhanced toughness and resilience of forged steel make it an excellent choice for applications exposed to harsh environmental conditions, ensuring longevity and reducing maintenance costs.

Moreover, steel industries forgings are essential in decorative applications. Their ability to be shaped into intricate designs allows architects and designers to create visually appealing elements while maintaining strength. Forged steel can be found in railings, gates, and decorative fixtures, where aesthetics meet functionality. The versatility of forged steel means it can be tailored to various design specifications, offering customization options that appeal to both residential and commercial projects.

The production of steel forgings involves several steps, including heating the metal to a specific temperature, forging it into the desired shape, and then heat treating to enhance its properties further. Advanced technologies, such as computer numerical control (CNC) machining, allow for precise shaping and finishing, ensuring that the final product meets stringent quality standards. This high level of precision is vital for components that must fit seamlessly within larger structures.

Furthermore, sustainability is becoming increasingly important in the steel industry. Many manufacturers are focusing on reducing their carbon footprint by utilizing recycled steel in their forging processes. This not only conserves raw materials but also promotes a circular economy within the construction materials market.

In conclusion, steel industries forgings are indispensable in the construction and decorative materials sector. Their unique combination of strength, aesthetic flexibility, and sustainability makes them a preferred choice for architects, engineers, and designers. As the demand for innovative and durable materials continues to grow, understanding the benefits and applications of steel forgings will enable industry professionals to make informed decisions that enhance the quality and appeal of their projects.

Latest developments

Exploring the Role of Steel Industries Forgings in Construction and Decorative Materials

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength, durability, and aesthetic appeal to a variety of applications. Forgings are formed by the shaping of metal using localized compressive forces, and they are produced through several techniques, including hammering, pressing, and rolling. This process improves the grain structure of

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components Table of Contents Understanding Stainless Steel The Importance of Forging in Manufacturing Types of Forging Processes Step-by-Step Forging Process Post-Forging Treatments and Finishes Common Applications of Forged Stainless Steel Components Challenges in Forging Stainless Steel FAQs About

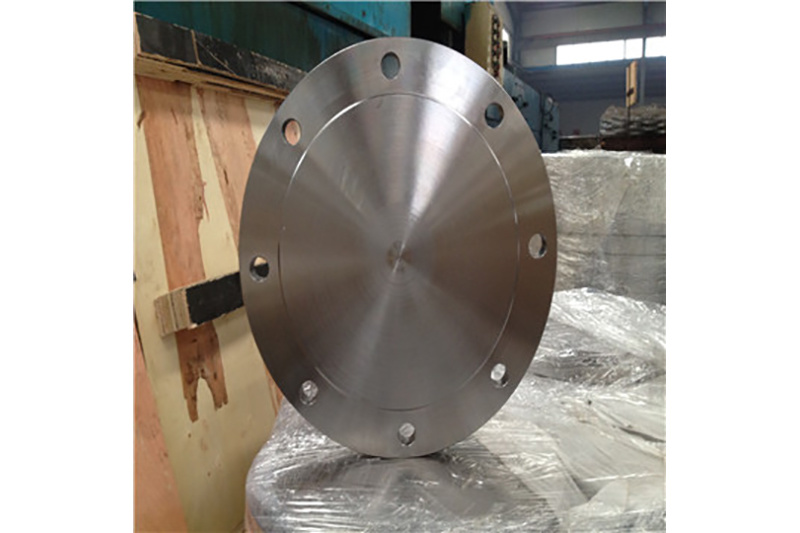

Non-standard flanges refer to flanges that do not conform to the typical sizes, shapes, or specifications established by industry standards such as ASTM or ASME. These specialized flanges are often designed to meet unique requirements in specific applications, making them a crucial component in various construction and pipefitting projects. One of the primary reasons for the use of non-standard f

Maximizing Performance with Japanese Standard Flanges in Your Pipeline

Maximizing Performance with Japanese Standard Flanges in Your Pipeline Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flanges: The Basics 3. Benefits of Japanese Standard Flanges 4. Applications of Japanese Standard Flanges in Various Industries 5. Selecting the Right Japanese Standard Flanges for Your Pipeline 6. Installation Tips for Japa

Understanding American Standard Flanges: Key Insights for Construction and Decoration Materials

American standard flanges are critical components in piping systems, particularly in the construction and decoration materials sector. They serve as connections between two sections of pipe, allowing for the secure assembly and disassembly of piping systems without compromising the integrity of the overall structure. Understanding the key attributes of American standard flanges can significantly e

Maintaining Your Threaded Flanges: Expert Tips for Longevity in Construction and Decoration

Maintaining Your Threaded Flanges: Tips for Longevity Table of Contents Understanding Threaded Flanges The Importance of Maintenance for Threaded Flanges Common Issues with Threaded Flanges and Their Solutions Best Practices for Maintaining Threaded Flanges Protective Coatings and Treatments for Threaded Flanges How to Inspect Threaded Flanges Effectively When to Repla