Understanding Flanged Connections: A Key Component in Building and Decorative Materials

Release time:

2025-07-05

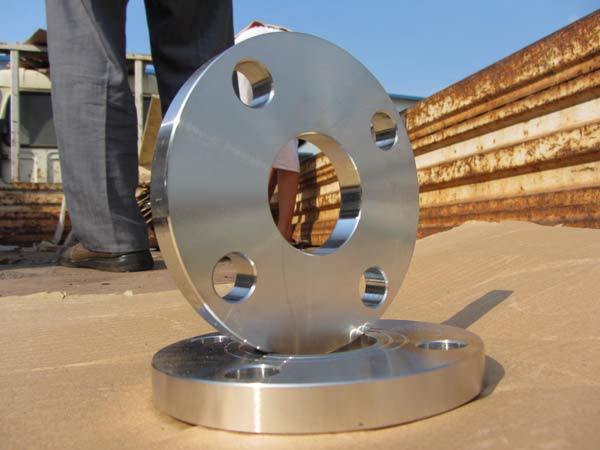

Flanged connections are integral components widely used in piping systems, particularly within the construction and decorative materials sector. These connections enable the joining of pipes, valves, pumps, and other equipment, ensuring a reliable and leak-proof assembly. The design of a flanged connection typically consists of two flanges facing each other, which are bolted together with a gasket

One of the primary advantages of flanged connections is their ease of assembly and disassembly. This feature is particularly beneficial in environments where maintenance and inspection are frequent. Unlike welded connections, flanged joints can be easily unbolted, allowing for quick access to piping systems without the need for specialized tools or skills. This not only saves time but also reduces labor costs during maintenance.

Flanged connections are available in various designs, including raised face, flat face, and tongue and groove types, catering to different application requirements. The choice of flange type often depends on the pressure and temperature conditions of the system, as well as the nature of the fluids being transported. For example, raised face flanges are commonly used in high-pressure systems, where a more reliable seal is necessary.

Another significant aspect of flanged connections is the importance of gasket selection. The gasket material must be compatible with the fluid being transported to prevent chemical reactions that could compromise the seal. Common gasket materials include rubber, PTFE, and metal, each offering unique properties that enhance the performance of the flanged connection in specific applications.

In addition to their practical benefits, flanged connections also contribute to the overall aesthetics of a system. In decorative material applications, visible flanges can be designed to complement the architectural style of a building or space. This versatility allows engineers and architects to incorporate functional components into their designs without sacrificing visual appeal.

Furthermore, proper installation and torqueing of bolts in flanged connections are critical to ensure long-lasting performance. Over-tightening can lead to flange warping or damage, while under-tightening may result in leaks. It is essential for professionals to follow manufacturer guidelines and industry standards when installing these connections.

In conclusion, flanged connections are vital elements in the realm of building and decorative materials, particularly in piping systems. Their ease of use, variety of designs, and importance in maintenance make them a preferred choice for professionals in the industry. Understanding the nuances of flanged connections, including gasket selection and installation practices, can significantly enhance system reliability and efficiency.

Latest developments

Understanding Flanged Connections: A Key Component in Building and Decorative Materials

Flanged connections are integral components widely used in piping systems, particularly within the construction and decorative materials sector. These connections enable the joining of pipes, valves, pumps, and other equipment, ensuring a reliable and leak-proof assembly. The design of a flanged connection typically consists of two flanges facing each other, which are bolted together with a gasket

Mastering Installation Techniques for Sliding Flanges in the Field

Mastering Installation Techniques for Sliding Flanges in the Field Table of Contents Introduction to Sliding Flanges Understanding Sliding Flanges and Their Applications Essential Tools for Sliding Flange Installation Preparation Steps for Flange Installation Step-by-Step Installation Process for Sliding Flanges Common Mistakes to Avoid During Installation Maintenance

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges play a pivotal role in the construction and decoration materials sector, especially in pipe fitting applications. These specialized flanges are characterized by their extended neck, which serves to enhance alignment and stability in piping systems. The design of high neck flanges allows for a smoother connection between pipes, minimizing the potential for leaks and ensuring a sec

Flat Flanges: A Comprehensive Guide for Contractors

Flat Flanges: A Comprehensive Guide for Contractors Table of Contents 1. Introduction to Flat Flanges 2. What Are Flat Flanges? 3. Types of Flat Flanges 4. Materials Used in Flat Flanges 5. Applications of Flat Flanges in Construction 6. Installation and Maintenance of Flat Flanges 7. Cost Considerations for Contractors 8. Common Issues and Solutions with Flat Flan

Exploring the Role of Steel Industries Forgings in Construction and Decorative Materials

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength, durability, and aesthetic appeal to a variety of applications. Forgings are formed by the shaping of metal using localized compressive forces, and they are produced through several techniques, including hammering, pressing, and rolling. This process improves the grain structure of

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components

Comprehensive Step-by-Step Guide to the Forging of Stainless Steel Components Table of Contents Understanding Stainless Steel The Importance of Forging in Manufacturing Types of Forging Processes Step-by-Step Forging Process Post-Forging Treatments and Finishes Common Applications of Forged Stainless Steel Components Challenges in Forging Stainless Steel FAQs About