Understanding the Material Options for Threaded Flanges: A Comprehensive Guide

Release time:

2025-07-06

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide Table of Contents 1. Introduction to Threaded Flanges 2. Importance of Material Selection for Threaded Flanges 3. Common Materials Used for Threaded Flanges 3.1 Carbon Steel Flanges 3.2 Stainless Steel Flanges 3.3 Duplex Steel Flanges 3.4 Alloy Steel

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide

Table of Contents

- 1. Introduction to Threaded Flanges

- 2. Importance of Material Selection for Threaded Flanges

- 3. Common Materials Used for Threaded Flanges

- 3.1 Carbon Steel Flanges

- 3.2 Stainless Steel Flanges

- 3.3 Duplex Steel Flanges

- 3.4 Alloy Steel Flanges

- 3.5 Plastic Flanges

- 4. Factors Influencing Material Selection for Threaded Flanges

- 5. Applications of Threaded Flanges in Various Industries

- 6. Installation and Maintenance of Threaded Flanges

- 7. Conclusion

- 8. Frequently Asked Questions (FAQs)

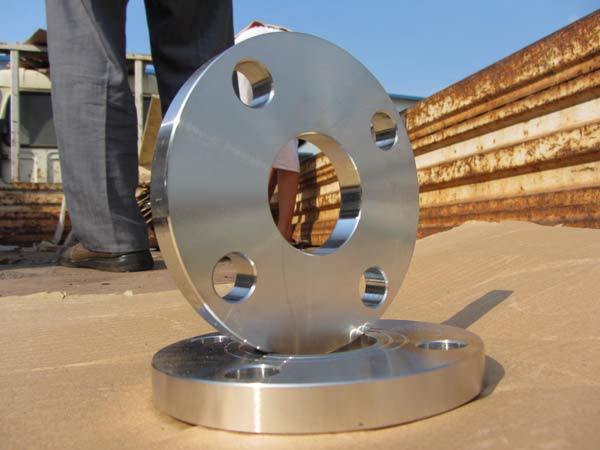

1. Introduction to Threaded Flanges

Threaded flanges are essential components in various piping systems, facilitating the connection of pipes, valves, and other equipment. Understanding the material options for these flanges is critical, as the correct choice can significantly influence the performance, durability, and safety of the piping system. This guide will navigate through the diverse material options available for threaded flanges, providing insights into their advantages and appropriate applications.

2. Importance of Material Selection for Threaded Flanges

Selecting the proper material for threaded flanges is crucial for multiple reasons:

- **Durability:** The material affects the lifespan and resistance to wear, corrosion, and extreme temperatures.

- **Compatibility:** Certain materials are better suited for specific fluids and gases, ensuring safety and efficacy.

- **Cost-Effectiveness:** Choosing the right material can lead to significant savings in maintenance and replacement costs.

- **Mechanical Performance:** Different materials have varying strengths and flexibility, impacting the overall integrity of the piping system.

3. Common Materials Used for Threaded Flanges

When it comes to threaded flanges, several materials dominate the market. Each material has its unique properties that make it suitable for specific applications.

3.1 Carbon Steel Flanges

Carbon steel is one of the most commonly used materials for threaded flanges due to its excellent mechanical properties and cost-effectiveness.

- **Advantages:** Carbon steel flanges exhibit high strength and rigidity, making them ideal for high-pressure applications. They are also relatively inexpensive compared to other materials.

- **Disadvantages:** However, carbon steel is prone to corrosion when exposed to moisture and harsh chemicals, necessitating protective coatings or paint.

3.2 Stainless Steel Flanges

Stainless steel flanges are known for their corrosion resistance, making them suitable for a variety of environments.

- **Advantages:** They offer excellent durability, high-temperature resistance, and hygiene, which is particularly advantageous in the food and pharmaceutical industries.

- **Disadvantages:** They are more expensive than carbon steel flanges and can be less suitable for high-pressure applications due to lower tensile strength.

3.3 Duplex Steel Flanges

Duplex steel flanges combine the best features of both austenitic and ferritic steels.

- **Advantages:** They provide high strength along with excellent resistance to stress corrosion cracking, making them suitable for harsh environments.

- **Disadvantages:** The cost of duplex steel flanges is higher due to the complex manufacturing processes required.

3.4 Alloy Steel Flanges

Alloy steel flanges are made by adding various elements to carbon steel to enhance its properties.

- **Advantages:** These flanges have improved mechanical properties, including higher strength and toughness. They are also suitable for high-temperature applications.

- **Disadvantages:** The presence of alloying elements can lead to increased costs and potential difficulties in welding.

3.5 Plastic Flanges

Plastic flanges, made from materials like PVC, CPVC, and polypropylene, are increasingly popular in specific applications.

- **Advantages:** They are lightweight, corrosion-resistant, and non-conductive. They are particularly useful in chemical processing where metal flanges may corrode.

- **Disadvantages:** Plastic flanges are less durable under high-pressure conditions and can be susceptible to damage from UV exposure.

4. Factors Influencing Material Selection for Threaded Flanges

When selecting the appropriate material for threaded flanges, several factors should be considered:

- **Operating Environment:** The temperature, pressure, and type of fluid being transported can significantly affect material performance.

- **Corrosion Resistance:** The potential for corrosion should be evaluated based on the fluids and environmental conditions.

- **Cost Considerations:** Budget constraints can influence material choice, balancing cost with performance needs.

- **Compliance and Standards:** Flanges must comply with industry standards and regulations, particularly in sensitive industries like oil and gas, food, and pharmaceuticals.

5. Applications of Threaded Flanges in Various Industries

Threaded flanges find applications across a broad range of industries, including:

- **Oil and Gas:** Used for connecting pipes that transport crude oil, natural gas, and other petrochemicals.

- **Chemical Processing:** Essential for pipelines carrying corrosive chemicals, where material selection is critical for safety.

- **Water Treatment:** Utilized in water treatment plants, where durability and resistance to corrosion are vital.

- **Manufacturing:** Common in various manufacturing processes, including those in the automotive and aerospace industries.

- **Food and Beverage:** Employed in sanitary applications where hygiene and cleanliness are paramount.

6. Installation and Maintenance of Threaded Flanges

Proper installation and maintenance of threaded flanges are crucial to ensuring long-term reliability and performance:

- **Installation Tips:**

- Ensure clean and even threads.

- Use appropriate sealants or gaskets to prevent leaks.

- Tighten bolts evenly and to the specified torque to avoid stress on the flange.

- **Maintenance Practices:**

- Regularly inspect for signs of corrosion or wear.

- Tighten bolts as necessary to account for any loosening over time.

- Replace any damaged flanges promptly to prevent leaks and system failures.

7. Conclusion

Understanding the material options for threaded flanges is essential for anyone involved in the design, installation, or maintenance of piping systems. By carefully evaluating the advantages and disadvantages of various materials, as well as considering factors such as operating conditions and cost, professionals can make informed decisions that ensure the safety and efficiency of their systems. Whether you choose carbon steel, stainless steel, duplex steel, alloy steel, or plastic flanges, the key is to align your choice with the specific requirements of your application.

8. Frequently Asked Questions (FAQs)

FAQ 1: What is the best material for threaded flanges?

The best material for threaded flanges depends on the specific application. Carbon steel is often used for general purposes, while stainless steel is preferred in corrosive environments.

FAQ 2: Are plastic flanges suitable for high-temperature applications?

Plastic flanges are generally not suitable for high-temperature applications as they may deform under heat.

FAQ 3: How can I prevent corrosion in threaded flanges?

To prevent corrosion, consider using flanges made from corrosion-resistant materials, applying protective coatings, and ensuring proper sealing.

FAQ 4: What industries commonly use threaded flanges?

Threaded flanges are commonly used in the oil and gas, chemical processing, water treatment, manufacturing, and food and beverage industries.

FAQ 5: How often should threaded flanges be inspected?

Threaded flanges should be inspected regularly, at least annually, or more frequently in critical applications to ensure they are free from corrosion and wear.

This article aims to provide a comprehensive overview of threaded flanges and their material options, ensuring that you have the knowledge to make the best choice for your needs.

Previous

Latest developments

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide Table of Contents 1. Introduction to Threaded Flanges 2. Importance of Material Selection for Threaded Flanges 3. Common Materials Used for Threaded Flanges 3.1 Carbon Steel Flanges 3.2 Stainless Steel Flanges 3.3 Duplex Steel Flanges 3.4 Alloy Steel

Understanding Flanged Connections: A Key Component in Building and Decorative Materials

Flanged connections are integral components widely used in piping systems, particularly within the construction and decorative materials sector. These connections enable the joining of pipes, valves, pumps, and other equipment, ensuring a reliable and leak-proof assembly. The design of a flanged connection typically consists of two flanges facing each other, which are bolted together with a gasket

Mastering Installation Techniques for Sliding Flanges in the Field

Mastering Installation Techniques for Sliding Flanges in the Field Table of Contents Introduction to Sliding Flanges Understanding Sliding Flanges and Their Applications Essential Tools for Sliding Flange Installation Preparation Steps for Flange Installation Step-by-Step Installation Process for Sliding Flanges Common Mistakes to Avoid During Installation Maintenance

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges play a pivotal role in the construction and decoration materials sector, especially in pipe fitting applications. These specialized flanges are characterized by their extended neck, which serves to enhance alignment and stability in piping systems. The design of high neck flanges allows for a smoother connection between pipes, minimizing the potential for leaks and ensuring a sec

Flat Flanges: A Comprehensive Guide for Contractors

Flat Flanges: A Comprehensive Guide for Contractors Table of Contents 1. Introduction to Flat Flanges 2. What Are Flat Flanges? 3. Types of Flat Flanges 4. Materials Used in Flat Flanges 5. Applications of Flat Flanges in Construction 6. Installation and Maintenance of Flat Flanges 7. Cost Considerations for Contractors 8. Common Issues and Solutions with Flat Flan

Exploring the Role of Steel Industries Forgings in Construction and Decorative Materials

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength, durability, and aesthetic appeal to a variety of applications. Forgings are formed by the shaping of metal using localized compressive forces, and they are produced through several techniques, including hammering, pressing, and rolling. This process improves the grain structure of