Understanding Non-Standard Flanges: Importance and Applications in Construction

Release time:

2025-07-09

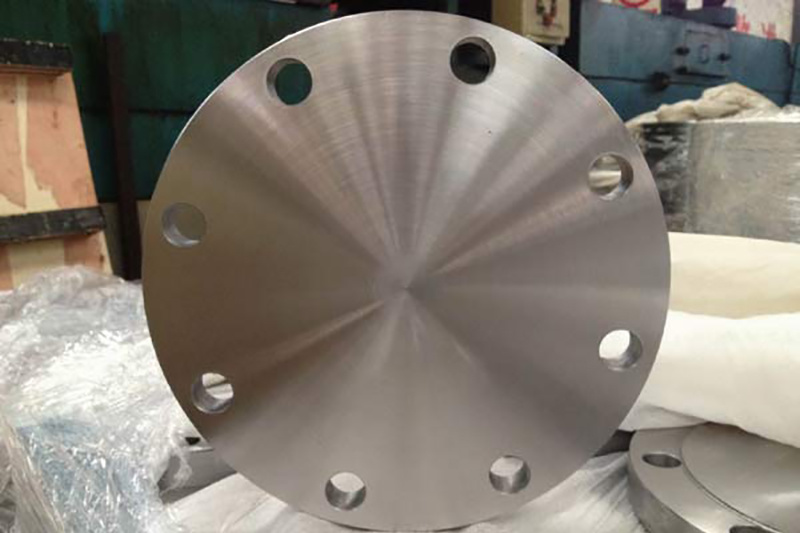

Non-standard flanges play a crucial role in the construction and decorative materials sector, particularly when it comes to piping and fitting systems. Unlike standard flanges, which adhere to universally accepted dimensions and specifications, non-standard flanges are tailored to meet the unique requirements of specific projects. This customization enables engineers and designers to address vario

One of the primary reasons for utilizing non-standard flanges is the need for a secure and efficient connection between pipes and fittings. In many cases, standard flanges may not provide the exact fit or alignment needed, leading to potential leaks or structural issues. Non-standard flanges can be designed to accommodate unique dimensions, shapes, or materials, ensuring a perfect fit and enhancing the overall integrity of the system. This is particularly important in applications where pressure and temperature variations are significant, as a proper seal is essential to prevent failures.

In addition to their functional advantages, non-standard flanges also offer aesthetic benefits in decorative applications. For instance, when designing architectural features or installations that require a specific look, custom flanges can be designed to complement the overall design scheme. This allows architects and designers to create visually appealing structures while maintaining the necessary functionality of the piping systems.

Another key aspect of non-standard flanges is their adaptability to various industrial standards. Different industries may require specific flange designs to comply with local regulations or operational needs. By using non-standard flanges, companies can ensure that their systems not only meet these standards but are also optimized for performance, safety, and longevity.

Furthermore, non-standard flanges can be beneficial in projects involving retrofitting or upgrading existing systems. In many cases, existing installations may have unique dimensions that do not align with current standard flange sizes. By utilizing non-standard flanges, engineers can seamlessly integrate new components with older systems, thus enhancing efficiency and reducing costs associated with complete system overhauls.

In summary, non-standard flanges are an integral component of the building and construction industry, particularly in the realm of piping and fittings. Their ability to address specific project needs, enhance system integrity, and provide aesthetic value makes them a valuable solution for engineers, designers, and contractors alike. By understanding the significance of non-standard flanges, industry professionals can make informed decisions that lead to better project outcomes and improved system performance.

Latest developments

Sustainability in Construction: The Case for Flat Flanges

Sustainability in Construction: The Case for Flat Flanges Table of Contents Introduction to Sustainability in Construction The Importance of Sustainability in the Construction Industry What are Flat Flanges? Benefits of Using Flat Flanges in Sustainable Construction Material Sourcing: Eco-Friendly Options for Flat Flanges Energy Efficiency: How Flat Flanges Contribute Cost-Effec

Understanding the Role of Steel Forgings in the Construction Industry

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength and reliability to various structural applications. Forging is a manufacturing process that involves shaping metal using compressive forces, which can be delivered through hammers or presses. This process results in a product that is notably stronger and more durable than its non-f

Why Forged Stainless Steel is Superior for High-Temperature Applications

Why Forged Stainless Steel is Superior for High-Temperature Applications Table of Contents 1. Introduction to Forged Stainless Steel 2. Understanding High-Temperature Applications 3. Benefits of Forged Stainless Steel 3.1 Strength and Durability 3.2 Corrosion Resistance 3.3 Thermal Stability 3.4 Cost-Effectiveness

Understanding Non-Standard Flanges: Importance and Applications in Construction

Non-standard flanges play a crucial role in the construction and decorative materials sector, particularly when it comes to piping and fitting systems. Unlike standard flanges, which adhere to universally accepted dimensions and specifications, non-standard flanges are tailored to meet the unique requirements of specific projects. This customization enables engineers and designers to address vario

A Comprehensive Guide to the Specifications of Japanese Standard Flanges

A Comprehensive Guide to the Specifications of Japanese Standard Flanges Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flange Types and Their Applications 2.1. Weld Neck Flanges 2.2. Slip-On Flanges 2.3. Socket Weld Flanges 2.4. Blind Flanges 3. Material Specifications for Japanese Standard Flanges 4. Key Standards Governing Japanese Flange Production 5. Advantage

Understanding American Standard Flanges: Key Features and Applications

American Standard flanges are critical components used in a variety of piping systems, particularly within the construction and decorative materials sector. Designed to provide a reliable connection between pipes, valves, and other equipment, these flanges operate by creating a seal that prevents leaks and maintains pressure within the system. Understanding the specifications and applications of A