A Comprehensive Guide to the Specifications of Japanese Standard Flanges

Release time:

2025-07-08

A Comprehensive Guide to the Specifications of Japanese Standard Flanges Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flange Types and Their Applications 2.1. Weld Neck Flanges 2.2. Slip-On Flanges 2.3. Socket Weld Flanges 2.4. Blind Flanges 3. Material Specifications for Japanese Standard Flanges 4. Key Standards Governing Japanese Flange Production 5. Advantage

A Comprehensive Guide to the Specifications of Japanese Standard Flanges

Table of Contents

1. Introduction to Japanese Standard Flanges

2. Understanding Flange Types and Their Applications

2.1. Weld Neck Flanges

2.2. Slip-On Flanges

2.3. Socket Weld Flanges

2.4. Blind Flanges

3. Material Specifications for Japanese Standard Flanges

4. Key Standards Governing Japanese Flange Production

5. Advantages of Using Japanese Standard Flanges

6. Considerations for Selecting the Right Flange

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Japanese Standard Flanges

Japanese standard flanges are essential components used in various piping systems, particularly within the construction and decorative materials sectors. They are critical for ensuring secure connections between pipes, valves, and other equipment. Understanding the specifications and standards associated with these flanges is vital for engineers, designers, and project managers. This article delves deeply into the types, materials, and applications of Japanese standard flanges and aims to provide a comprehensive understanding for professionals in the field.

2. Understanding Flange Types and Their Applications

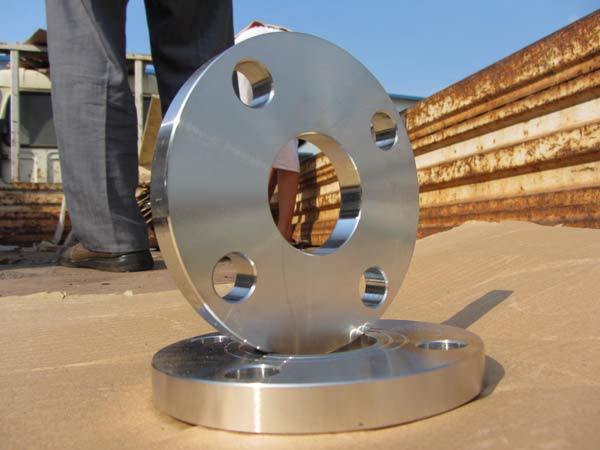

Flanges come in various shapes and sizes, each designed to meet specific requirements. Below, we discuss some of the most common types of Japanese standard flanges and their respective applications.

2.1. Weld Neck Flanges

Weld neck flanges are designed with a long tapered neck that allows for welding directly to the pipe. This design provides a strong joint and is ideal for high-pressure applications. Typically, they are used in environments where safety and reliability are paramount, such as in oil and gas pipelines.

2.2. Slip-On Flanges

Slip-on flanges are made to slide over the pipe and are then welded in place. This type of flange is easier to align and install, making it a popular choice for low-pressure applications. They are often found in non-critical systems, such as water and wastewater treatment facilities.

2.3. Socket Weld Flanges

Socket weld flanges are designed for use with pipes of smaller diameters. They feature a socket that the pipe fits into before being welded. This type of flange is suitable for high-pressure and high-temperature systems, making them ideal for chemical processing and power generation applications.

2.4. Blind Flanges

Blind flanges are solid disks used to seal the end of a piping system. They are an excellent solution for closing off pipelines and enabling future access for maintenance. Blind flanges are commonly used in industrial and commercial applications to ensure safety and integrity.

3. Material Specifications for Japanese Standard Flanges

The material used for manufacturing flanges significantly affects their performance and durability. Various materials are commonly used for Japanese standard flanges:

- **Carbon Steel:** Known for its strength and durability, carbon steel is commonly used in general piping applications.

- **Stainless Steel:** Offers excellent corrosion resistance, making it ideal for chemical and food processing applications.

- **Alloy Steel:** Used in high-temperature and high-pressure environments, alloy steel flanges can withstand extreme conditions.

- **Plastic and Composite Materials:** Increasingly popular for specific applications due to their lightweight and corrosion-resistant properties.

Choosing the right material is crucial for the performance and longevity of the flange in its application.

4. Key Standards Governing Japanese Flange Production

Japanese standard flanges adhere to specific industry standards that dictate their quality and specifications. Key standards include:

- **JIS (Japanese Industrial Standards):** These guidelines provide comprehensive specifications for flange dimensions, tolerances, and material properties.

- **JIS B 2220:** This standard outlines the dimensions and rating of pipe flanges in Japan, ensuring uniformity and safety.

- **ISO (International Organization for Standardization) Standards:** Many Japanese flanges also conform to international standards to facilitate global trade and compatibility.

Compliance with these standards guarantees that flanges meet the required safety and performance criteria.

5. Advantages of Using Japanese Standard Flanges

Utilizing Japanese standard flanges offers several advantages:

- **Quality Assurance:** The strict adherence to JIS and ISO standards ensures high-quality products.

- **Versatility:** A wide range of flange types and materials allows for their use in various applications.

- **Durability:** Japanese flanges are designed to withstand challenging environmental conditions, enhancing the longevity of piping systems.

- **Interchangeability:** Standardization means that flanges can be easily replaced or integrated with other systems, minimizing downtime and maintenance costs.

These advantages make Japanese standard flanges a preferred choice for many engineering projects.

6. Considerations for Selecting the Right Flange

When selecting a flange for a specific application, several factors must be considered:

- **Pressure and Temperature Rating:** Ensure that the flange can handle the maximum pressure and temperature of the system.

- **Material Compatibility:** Choose a material that is compatible with the fluids or gases flowing through the pipes.

- **Corrosion Resistance:** Evaluate the environment in which the flange will be used and select materials that resist corrosion effectively.

- **Installation and Maintenance:** Consider the ease of installation and future maintenance requirements when selecting the appropriate flange type.

Understanding these factors helps ensure the longevity and safety of the piping system.

7. Frequently Asked Questions (FAQs)

**Q1: What are the common applications for Japanese standard flanges?**

A1: Japanese standard flanges are used in various applications, including oil and gas pipelines, chemical processing, water treatment facilities, and construction projects.

**Q2: How do I determine the correct flange size?**

A2: The correct flange size can be determined by measuring the diameter of the pipe and considering the pressure and temperature requirements. Reference JIS B 2220 for standard dimensions.

**Q3: Are Japanese standard flanges interchangeable with other flange types?**

A3: While many Japanese standard flanges are designed to meet international standards, compatibility will depend on specific dimensions and pressure ratings. Always verify before interchanging flanges.

**Q4: What is the difference between slip-on and weld neck flanges?**

A4: Slip-on flanges slide over the pipe and are welded in place, making them easier to install, while weld neck flanges have a long neck for welding directly to the pipe, providing a stronger joint suitable for high-pressure applications.

**Q5: How do I maintain flanges in a piping system?**

A5: Regular inspections for corrosion, leaks, and mechanical integrity should be performed. Ensure proper sealing and replace any damaged flanges promptly to maintain system safety.

8. Conclusion

In conclusion, Japanese standard flanges are integral components in various piping systems across multiple industries. Understanding their specifications, types, and applications can significantly enhance project outcomes and operational efficiency. By selecting the right flange based on material, design, and compliance with industry standards, engineers and designers can ensure the reliability and safety of their piping systems. As the industry continues to evolve, staying informed about the latest developments and standards in flange specifications will be crucial for success.

Latest developments

A Comprehensive Guide to the Specifications of Japanese Standard Flanges

A Comprehensive Guide to the Specifications of Japanese Standard Flanges Table of Contents 1. Introduction to Japanese Standard Flanges 2. Understanding Flange Types and Their Applications 2.1. Weld Neck Flanges 2.2. Slip-On Flanges 2.3. Socket Weld Flanges 2.4. Blind Flanges 3. Material Specifications for Japanese Standard Flanges 4. Key Standards Governing Japanese Flange Production 5. Advantage

Understanding American Standard Flanges: Key Features and Applications

American Standard flanges are critical components used in a variety of piping systems, particularly within the construction and decorative materials sector. Designed to provide a reliable connection between pipes, valves, and other equipment, these flanges operate by creating a seal that prevents leaks and maintains pressure within the system. Understanding the specifications and applications of A

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide

Understanding the Material Options for Threaded Flanges: A Comprehensive Guide Table of Contents 1. Introduction to Threaded Flanges 2. Importance of Material Selection for Threaded Flanges 3. Common Materials Used for Threaded Flanges 3.1 Carbon Steel Flanges 3.2 Stainless Steel Flanges 3.3 Duplex Steel Flanges 3.4 Alloy Steel

Understanding Flanged Connections: A Key Component in Building and Decorative Materials

Flanged connections are integral components widely used in piping systems, particularly within the construction and decorative materials sector. These connections enable the joining of pipes, valves, pumps, and other equipment, ensuring a reliable and leak-proof assembly. The design of a flanged connection typically consists of two flanges facing each other, which are bolted together with a gasket

Mastering Installation Techniques for Sliding Flanges in the Field

Mastering Installation Techniques for Sliding Flanges in the Field Table of Contents Introduction to Sliding Flanges Understanding Sliding Flanges and Their Applications Essential Tools for Sliding Flange Installation Preparation Steps for Flange Installation Step-by-Step Installation Process for Sliding Flanges Common Mistakes to Avoid During Installation Maintenance

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges play a pivotal role in the construction and decoration materials sector, especially in pipe fitting applications. These specialized flanges are characterized by their extended neck, which serves to enhance alignment and stability in piping systems. The design of high neck flanges allows for a smoother connection between pipes, minimizing the potential for leaks and ensuring a sec