Understanding High Neck Flanges: Essential Components in Construction and Decoration

Release time:

2025-07-13

High neck flanges are specialized components commonly used in the construction and decoration materials industry, particularly in the realm of piping and fittings. These flanges are characterized by their extended neck, which provides added height and a robust sealing surface. This unique design feature not only enhances their structural integrity but also facilitates easier alignment and installa

One of the primary functions of a high neck flange is to connect pipes, valves, pumps, and other equipment within a piping system. By providing a secure and durable joint, they play a critical role in maintaining the overall integrity of the system, preventing leaks, and ensuring optimal performance. High neck flanges are especially advantageous in applications requiring high pressure and temperature resistance, making them a preferred choice in industries such as oil and gas, chemical processing, and water treatment.

The extended neck design of high neck flanges contributes to a significant increase in the surface area for sealing. This is particularly beneficial when dealing with fluids and gases under pressure, as it helps to distribute stress more evenly across the flange, reducing the risk of deformation or failure over time. Additionally, the height of the neck allows for better alignment with the connecting components, which can simplify the installation process and minimize the potential for errors.

When selecting high neck flanges for a project, professionals should consider several factors, including material compatibility, pressure ratings, and the specific application requirements. High neck flanges are available in various materials, such as stainless steel, carbon steel, and alloy materials, each offering distinct advantages based on the operating environment. For example, stainless steel high neck flanges are highly resistant to corrosion, making them ideal for applications in harsh environments.

Moreover, it’s essential to adhere to industry standards and regulations when choosing high neck flanges to ensure safety and reliability. Standards such as ASME (American Society of Mechanical Engineers) or ANSI (American National Standards Institute) provide guidelines on dimensions, tolerances, and testing methods, ensuring that the flanges meet the necessary performance criteria.

In conclusion, high neck flanges are indispensable components in the construction and decoration materials industry. Their unique design features, such as the extended neck, enhance sealing capabilities and installation efficiency, making them suitable for a wide range of applications. By understanding the characteristics and advantages of high neck flanges, professionals can make informed decisions that contribute to the success of their projects, ensuring safety, reliability, and optimal performance in various piping systems.

Latest developments

The Importance of Threaded Flanges in Plumbing Applications

The Importance of Threaded Flanges in Plumbing Applications Table of Contents 1. Understanding Threaded Flanges 2. Types of Threaded Flanges 3. Key Benefits of Using Threaded Flanges 3.1 Enhanced Connection Integrity 3.2 Ease of Installation and Maintenance 3.3 Versatility in Applications 4. Installation Techniques for Threaded Flanges 4.1 Preparing the Pipe Ends 4.2 Ensuring P

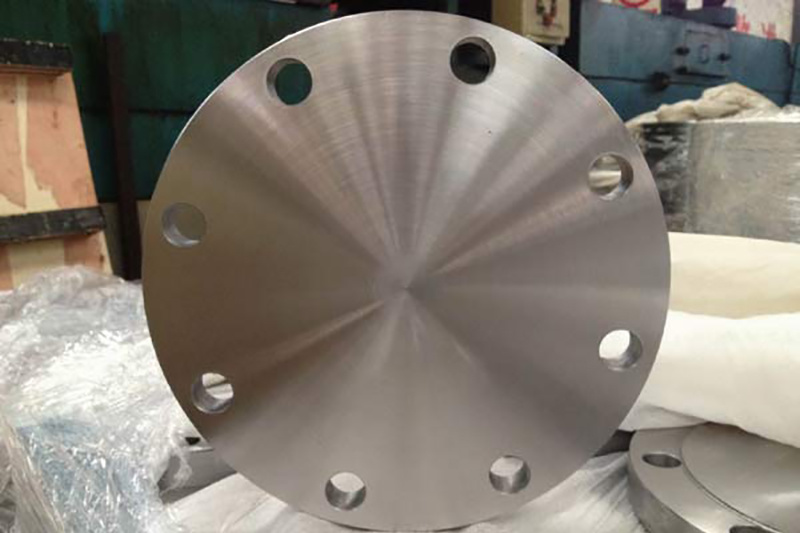

Blind Flanges: Where and Why They Matter in Everyday Piping Systems

When it comes to piping systems, one component that often goes unnoticed but plays a crucial role is the Blind flange. These simple yet effective discs are used to seal off the end of a pipe, valve, or vessel, ensuring safety and preventing leaks. But where exactly are they used, and why should users care about choosing the right one—whether it’s a quality Blind flange or a more cheap Blind flange option? Let’s break it down.

Flanged Connections: The Unsung Heroes of Piping Systems

When you think about piping systems, flanged connections might not be the first thing that comes to mind. Yet, these simple but essential components are what keep everything securely linked—whether in a factory, a water treatment plant, or even a brewery. So, where exactly do flanged connections shine, and why should users care about choosing the right one? Let’s explore.

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges are specialized components commonly used in the construction and decoration materials industry, particularly in the realm of piping and fittings. These flanges are characterized by their extended neck, which provides added height and a robust sealing surface. This unique design feature not only enhances their structural integrity but also facilitates easier alignment and installa

Sustainability in Construction: The Case for Flat Flanges

Sustainability in Construction: The Case for Flat Flanges Table of Contents Introduction to Sustainability in Construction The Importance of Sustainability in the Construction Industry What are Flat Flanges? Benefits of Using Flat Flanges in Sustainable Construction Material Sourcing: Eco-Friendly Options for Flat Flanges Energy Efficiency: How Flat Flanges Contribute Cost-Effec

Understanding the Role of Steel Forgings in the Construction Industry

Steel industries forgings play a crucial role in the construction and decorative materials sector, providing strength and reliability to various structural applications. Forging is a manufacturing process that involves shaping metal using compressive forces, which can be delivered through hammers or presses. This process results in a product that is notably stronger and more durable than its non-f