Common Mistakes When Using Flat Flanges and How to Avoid Them

Release time:

2025-06-12

Common Mistakes When Using Flat Flanges and How to Avoid Them Flat flanges play a vital role in various industrial applications, especially in construction and plumbing. These components are crucial for connecting pipes, valves, and other equipment, ensuring a leak-proof and secure assembly. However, improper usage can lead to significant issues, such as leaks, equipment failure, and costly repair

Common Mistakes When Using Flat Flanges and How to Avoid Them

Flat flanges play a vital role in various industrial applications, especially in construction and plumbing. These components are crucial for connecting pipes, valves, and other equipment, ensuring a leak-proof and secure assembly. However, improper usage can lead to significant issues, such as leaks, equipment failure, and costly repairs. In this article, we will delve into common mistakes associated with flat flanges and provide actionable strategies to avoid them.

Table of Contents

1. Understanding Flat Flanges

2. Importance of Proper Installation Techniques

2.1. The Role of Gaskets

2.2. Torque Specifications

3. Material Compatibility and Selection

4. Common Mistakes in Flat Flange Applications

4.1. Inadequate Surface Preparation

4.2. Misalignment Issues

4.3. Over-tightening or Under-tightening Bolts

5. Maintenance Best Practices

6. Troubleshooting Common Problems

7. Frequently Asked Questions (FAQs)

8. Conclusion

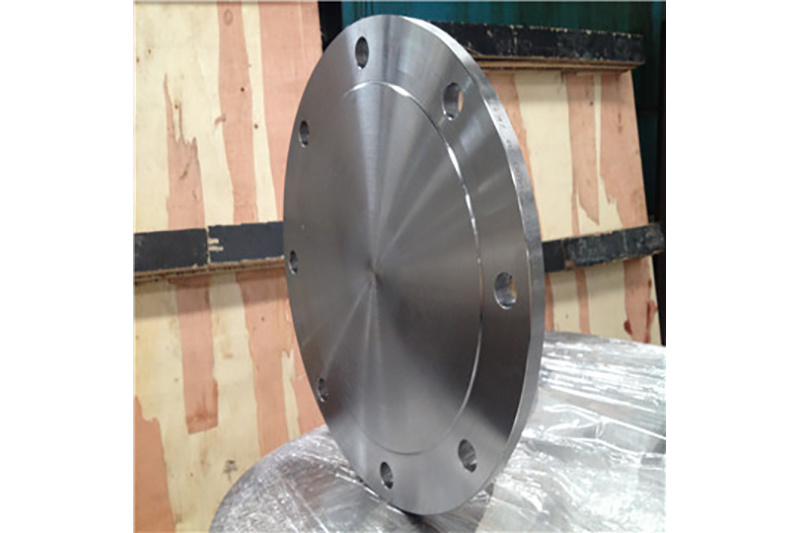

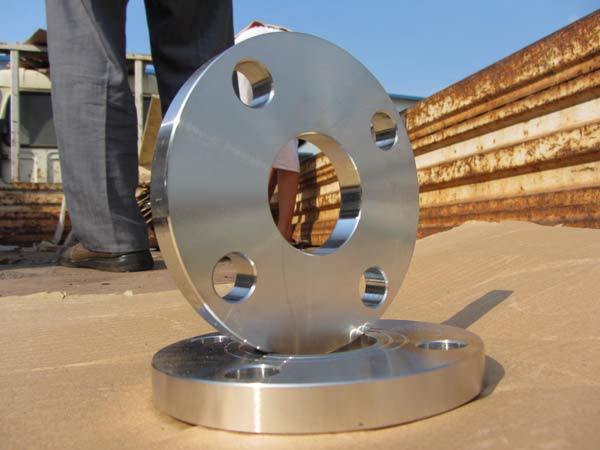

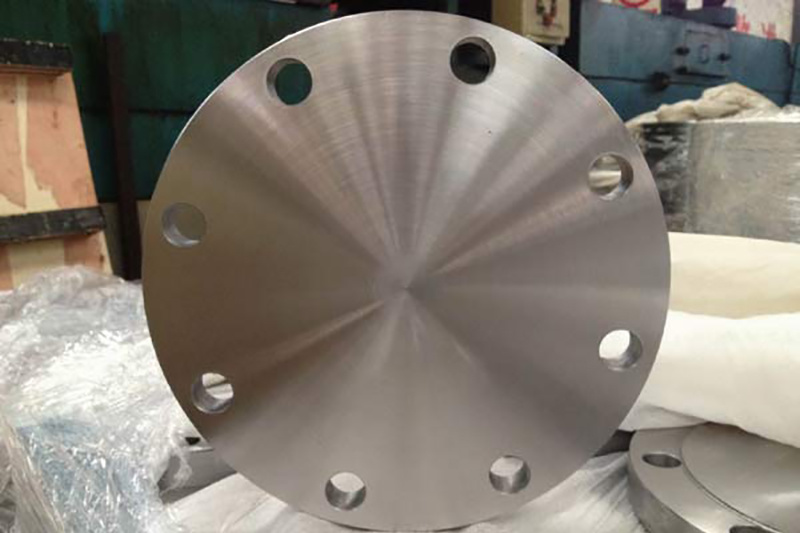

1. Understanding Flat Flanges

Flat flanges are mechanical components used to connect various piping systems. They come in different grades, sizes, and materials, making them versatile for numerous applications. Understanding the specifications and functionalities of flat flanges is paramount for successful implementation. These components can handle various pressures and temperatures, contributing to their widespread use in industries such as oil and gas, water treatment, and construction.

2. Importance of Proper Installation Techniques

Correct installation is essential to ensure that flat flanges perform effectively. Any oversight during installation can lead to severe repercussions, including leaks and structural failures.

2.1. The Role of Gaskets

Gaskets are critical in flat flange assemblies. They serve as a sealing mechanism, preventing leaks between the joints. When selecting gaskets, always ensure they are compatible with the fluid being transported and can withstand the operating temperature and pressure.

2.2. Torque Specifications

Following accurate torque specifications is essential. Insufficient torque can lead to joint loosening, while excessive torque can warp the flanges or damage the gaskets. Always consult the manufacturer's guidelines to determine the appropriate torque settings.

3. Material Compatibility and Selection

Choosing the right materials for flat flanges is vital. Different materials have varying properties and applications. For instance, stainless steel flanges are ideal for corrosive environments, while carbon steel flanges are suitable for non-corrosive applications. Always evaluate the working environment and media to select the best material.

4. Common Mistakes in Flat Flange Applications

Numerous errors can occur when working with flat flanges. Recognizing these mistakes can help prevent future complications.

4.1. Inadequate Surface Preparation

One of the most significant mistakes is failing to prepare the surfaces properly. Dirty, uneven, or corroded surfaces can compromise the integrity of the joint. Always clean and inspect the surfaces before installation to ensure a secure seal.

4.2. Misalignment Issues

Flange misalignment is another common problem. Misaligned flanges can lead to uneven pressure distribution, resulting in leaks or even catastrophic failures. Use alignment tools and techniques to ensure the flanges are properly positioned before tightening.

4.3. Over-tightening or Under-tightening Bolts

Improperly torqued bolts can create significant problems. Over-tightening can cause flange deformation, while under-tightening can lead to joint failure due to leaks. Always adhere to the recommended torque values and use a torque wrench for accuracy.

5. Maintenance Best Practices

Regular maintenance is crucial for ensuring the longevity and functionality of flat flanges. Implementing a structured maintenance routine can help identify potential issues before they escalate.

1. **Regular Inspections**: Conduct frequent inspections to check for signs of wear, corrosion, or leaks. Early detection can prevent more significant problems later on.

2. **Cleaning**: Keep the flanges clean and free from debris. Accumulation of dirt can lead to corrosion and affect the joint's integrity.

3. **Re-torquing**: Periodically check the torque on the bolts, especially after initial installation. Vibrations and temperature changes can cause bolts to loosen over time.

6. Troubleshooting Common Problems

Despite following best practices, issues can still arise. Knowing how to troubleshoot common problems can save time and resources.

- **Leakage**: If you notice leaks, first check the torque and surface preparation. If the issue persists, inspect the gasket for damage and replace it if necessary.

- **Corrosion**: In cases of corrosion, evaluate the material compatibility. Consider applying protective coatings or switching to a more suitable material for corrosive environments.

- **Unusual Noises or Vibrations**: These could indicate misalignment or improper tightening. Re-assess the installation and adjust accordingly.

7. Frequently Asked Questions (FAQs)

**Q1: What materials are best for flat flanges?**

A1: Stainless steel and carbon steel are commonly used. The choice depends on the specific application and environmental conditions.

**Q2: How often should flat flanges be inspected?**

A2: Regular inspections should be conducted at least quarterly or more frequently in critical applications.

**Q3: Can I use any gasket with flat flanges?**

A3: No, always select a gasket that is compatible with the fluid being transported and can withstand the operating conditions.

**Q4: What are the signs of flange misalignment?**

A4: Signs include uneven wear, leaks, and unusual vibrations during operation.

**Q5: How can I improve the sealing of flat flanges?**

A5: Proper surface preparation, the correct gasket selection, and accurate torque application are essential for effective sealing.

8. Conclusion

Understanding and avoiding common mistakes when using flat flanges is essential for ensuring safe and effective operations. By focusing on proper installation techniques, selecting the right materials, and adhering to maintenance best practices, users can enhance the longevity and performance of their flange connections. Implementing the strategies outlined in this article will help prevent costly errors and ensure the integrity of your piping systems. By remaining vigilant and proactive, we can avoid the pitfalls commonly associated with flat flanges, ultimately achieving success in our construction and plumbing projects.

Latest developments

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Understanding Flanged Connections in Construction and Decor Materials

Flanged connections are mechanical joints that consist of two flanges, bolted together to create a tight seal. These connections are essential in the construction and decorative materials industry, especially in plumbing and piping systems where fluid transport is critical. The choice of flanged connections can significantly affect the integrity and efficiency of piping systems, making it vital fo

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, a specialized type of flange, are designed with an extended neck that provides additional height. This design not only facilitates an increased surface area for welding but also assists in alignment, making them ideal for various applications in piping systems. The extended neck allows for a better connection to pipes and creates a more robust sealing surface, reducing the risk