What is the difference between carbon steel flanges and stainless steel flanges?

Release time:

2021-06-02

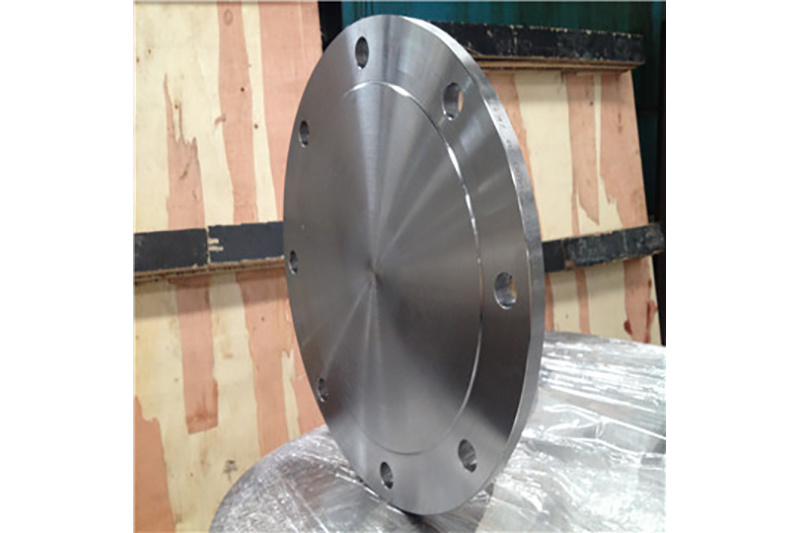

A flange is a disc-shaped component that is commonly used in piping engineering. Flanges are always used in pairs. In piping engineering, flanges are mainly used for connecting pipes. For pipes that need to be connected, a flange plate is installed. Low-pressure pipes can use threaded flanges, while welded flanges are used for pressures above 4 kg. A sealing gasket is added between the two flange plates and then fastened with bolts. Flanges of different pressures have different thicknesses and use different bolts.

A flange is a disc-shaped part that is commonly used in pipeline engineering. Flanges are always used in pairs. In pipeline engineering, flanges are mainly used for connecting pipes. For pipes that need to be connected, a flange plate is installed. Low-pressure pipes can use threaded flanges, while welded flanges are used for pressures above 4 kg. A sealing gasket is added between the two flange plates, which are then fastened with bolts. Flanges of different pressures have different thicknesses and use different bolts.

Main functions of flanges: 1. Connect pipelines and maintain the sealing performance of the pipelines; 2. Facilitate the replacement of a section of the pipeline; 3. Facilitate disassembly to inspect the condition of the pipeline; 4. Facilitate the closure of a section of the pipeline.

Stainless steel flange: A flange (Flange) is also called a flange plate or rim. A flange is a part that connects pipes to each other, connected at the pipe ends. The flange has holes, and bolts tightly connect the two flanges. Gaskets are used for sealing between flanges. Flanges are divided into threaded connection (screw connection) flanges and welded flanges.

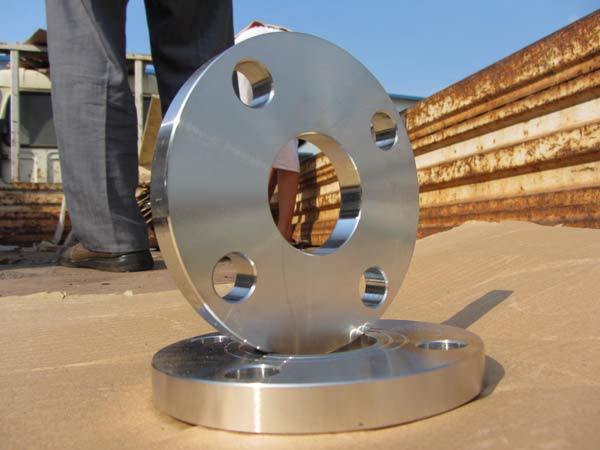

Carbon steel is steel that does not have alloy elements added specifically, while stainless steel is steel that has a high alloy content added to prevent rust. Stainless steel is much more expensive than carbon steel. These two types of steel have different applications and cannot be compared in terms of quality. Carbon steel usually has higher strength than stainless steel but is prone to rust. Common classifications of carbon steel include hot-rolled, cold-rolled, galvanized, silicon steel, rebar, wire rod, and channel steel; the main categories of stainless steel include series 200, 300, 400, 500, 600, and 900.

The difference between carbon steel flanges and stainless steel flanges lies in the addition of alloy elements such as nickel, chromium, molybdenum, titanium, and niobium in stainless steel flanges. Additionally, not all stainless steel flanges are rust-proof; they can only resist rust or prolong rusting time under the conditions allowed for various stainless steel materials.

Latest developments

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Understanding Flanged Connections in Construction and Decor Materials

Flanged connections are mechanical joints that consist of two flanges, bolted together to create a tight seal. These connections are essential in the construction and decorative materials industry, especially in plumbing and piping systems where fluid transport is critical. The choice of flanged connections can significantly affect the integrity and efficiency of piping systems, making it vital fo

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, a specialized type of flange, are designed with an extended neck that provides additional height. This design not only facilitates an increased surface area for welding but also assists in alignment, making them ideal for various applications in piping systems. The extended neck allows for a better connection to pipes and creates a more robust sealing surface, reducing the risk