Technical conditions and characteristics of carbon steel flanges!

Release time:

2021-07-07

The other meaning of carbon steel flange is: a flange plate produced according to the size, tolerance range, and other requirements of national standards, distinguished from flanges produced without standard sizes, also known as secondary standard flanges (it is incorrect for some to call them non-standard flanges). Usually, some unscrupulous merchants will reduce the thickness and outer diameter of the flange plate to save materials, and they also use waste steel or scrap steel to process flanges.

Another meaning of carbon steel flange is: a flange plate produced according to the size, tolerance range, etc. required by national standards, distinguished from flanges produced without standard sizes, also known as second standard flanges (it is incorrect to call them non-standard flanges). Usually, some unscrupulous merchants will reduce the thickness and outer diameter of the flange plate to save materials, and also use waste steel or scrap steel to process flanges.

Typically, this type of steel is substandard scrap with inadequate chemical composition and mechanical properties. Even worse, some black steel mills produce flanges using privately smelted steel, which employs outdated steelmaking techniques that cannot guarantee mechanical and welding properties. When used, it may not weld properly with steel pipes, or the steel itself may have cracks, pores, etc., leading to leaks after welding. Therefore, when purchasing flange plates, it is advisable to choose carbon steel flanges.

Carbon steel flanges are tight and reliable. They have two sealing surfaces, and the sealing surface material of the ball valve widely uses various plastics, ensuring good sealing and achieving complete sealing. Due to the wiping nature of carbon steel flanges during opening and closing, they can be used in media containing suspended solid particles. Model Q41F--16C Q41F--25C American standard A105 is approximately 0.9% (the standard is 1.05Max, which can decrease to 1.65%Max as carbon content decreases), while the national standard 16Mn content is about 1.3% (standard 1.2%~1.6%). The Japanese standard S25C is relatively low, below 0.6%.

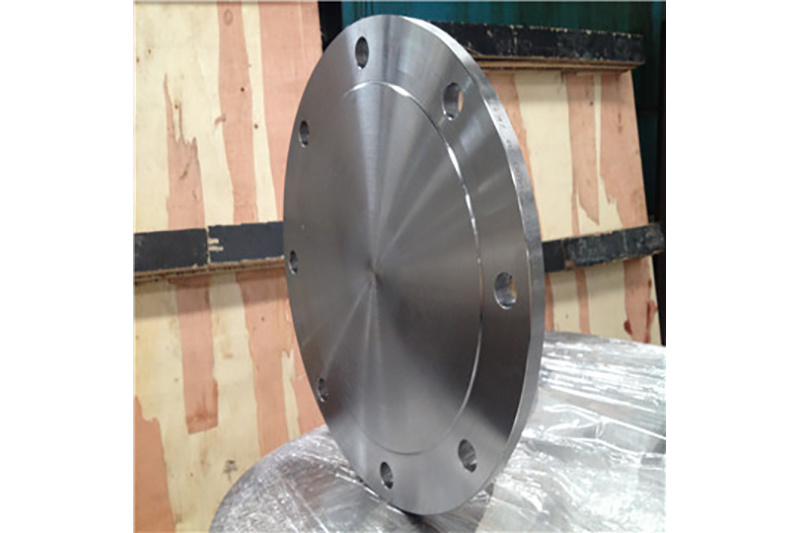

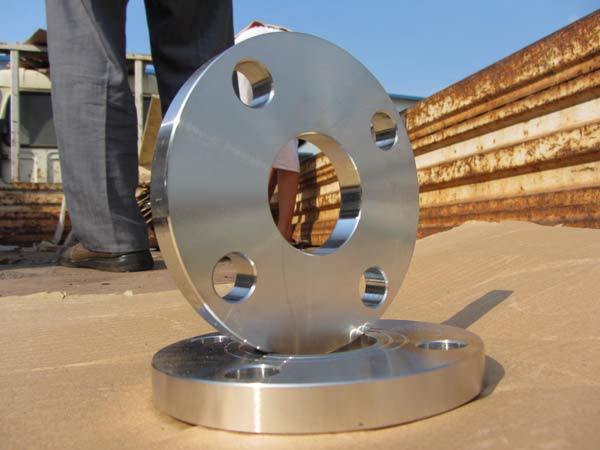

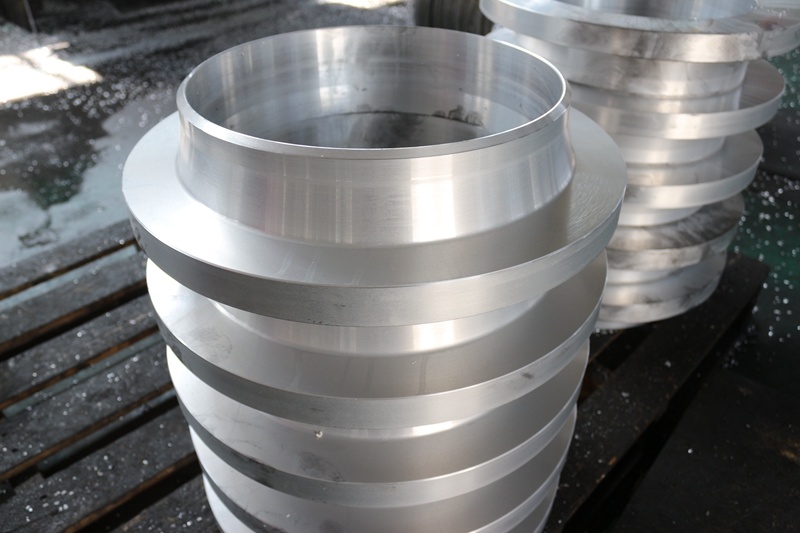

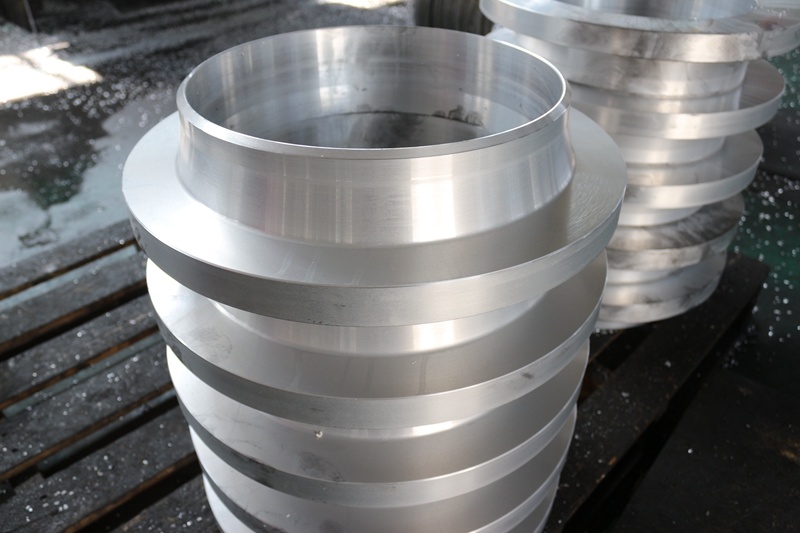

The production processes for carbon steel flanges include forging, casting, plate rolling, and plate cutting, among others. Among these, forging is the most expensive, followed by plate products, and casting products are the least expensive. In terms of quality, forging is the best, rolling is second, and casting is third. However, the caliber of forged products is generally smaller.

Latest developments

The Connection Between Japanese Standard Flanges and Sustainable Construction

The Connection Between Japanese Standard Flanges and Sustainable Construction Table of Contents 1. Understanding Japanese Standard Flanges 2. The Importance of Sustainable Construction 3. Key Features of Japanese Standard Flanges 3.1 Material Composition and Environmental Impact 3.2 Precision Engineering and Quality Assurance 4. How Japanese Standard Flanges Promote Sustainability 4.1 Energy Effic

Understanding American Standard Flanges: Essential Components in Construction and Decoration

American standard flanges are integral fittings used to connect two sections of piping or to connect piping to other components such as valves and pumps. Their design complies with specific standards established by the American National Standards Institute (ANSI), ensuring compatibility and reliability across various applications. These flanges are widely utilized in plumbing, heating, and various

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs?

Threaded Flanges vs. Welded Flanges: Which Is Better for Your Needs? When it comes to piping systems, the choice between threaded flanges and welded flanges can greatly influence the performance, durability, and overall quality of your installations. Understanding the characteristics of each type can help you make an informed decision tailored to your specific requirements. In this article, we wil

Understanding Flanged Connections in Construction and Decor Materials

Flanged connections are mechanical joints that consist of two flanges, bolted together to create a tight seal. These connections are essential in the construction and decorative materials industry, especially in plumbing and piping systems where fluid transport is critical. The choice of flanged connections can significantly affect the integrity and efficiency of piping systems, making it vital fo

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture

Sliding Flanges: The Key to Flexible Pipe Systems in Architecture In the ever-evolving landscape of architectural design and infrastructure, the need for flexibility and adaptability has never been more paramount. Among the various components that facilitate this flexibility, sliding flanges stand out as crucial elements in pipe systems. They enable efficient connections and adjustments, ensuring

Understanding High Neck Flanges: Essential Components in Construction and Decoration

High neck flanges, a specialized type of flange, are designed with an extended neck that provides additional height. This design not only facilitates an increased surface area for welding but also assists in alignment, making them ideal for various applications in piping systems. The extended neck allows for a better connection to pipes and creates a more robust sealing surface, reducing the risk